Application areas of expansion joints

Cost-effective complete solutions for sustainable processes.

The application spectrum encompasses everything from plant engineering and power plant construction to process technology, and from the paper and pulp industry to the chemical industry. The aim is to always provide sustainable benefits so that production processes run smoothly. That’s why Frenzelit has such a good reputation among countless industrial companies around the world.

A few practical examples are shown in the following – with solutions for your field, too:

Mobility

Gas turbine exhaust systems

- Type 1.131/03

- Temperature: 570 °C

- Pressure: 40 mbar

- Movement: 50 mm in all directions

- Application: GT units for commercial shipping and marine

Seal in gas duct and ship design

- Type 1.422

- Temperature: 500°C

- Pressure: 5 mbar

- Movement: axial: 40 mm, lateral: 10 mm

- Application: Yachts

Gas tank seal

- Type 1.201

- Temperature: 150°C

- Pressure: 100 mbar

- Movement: axial 40 mm, lateral: 10 mm

- Application: LPG gas tanker

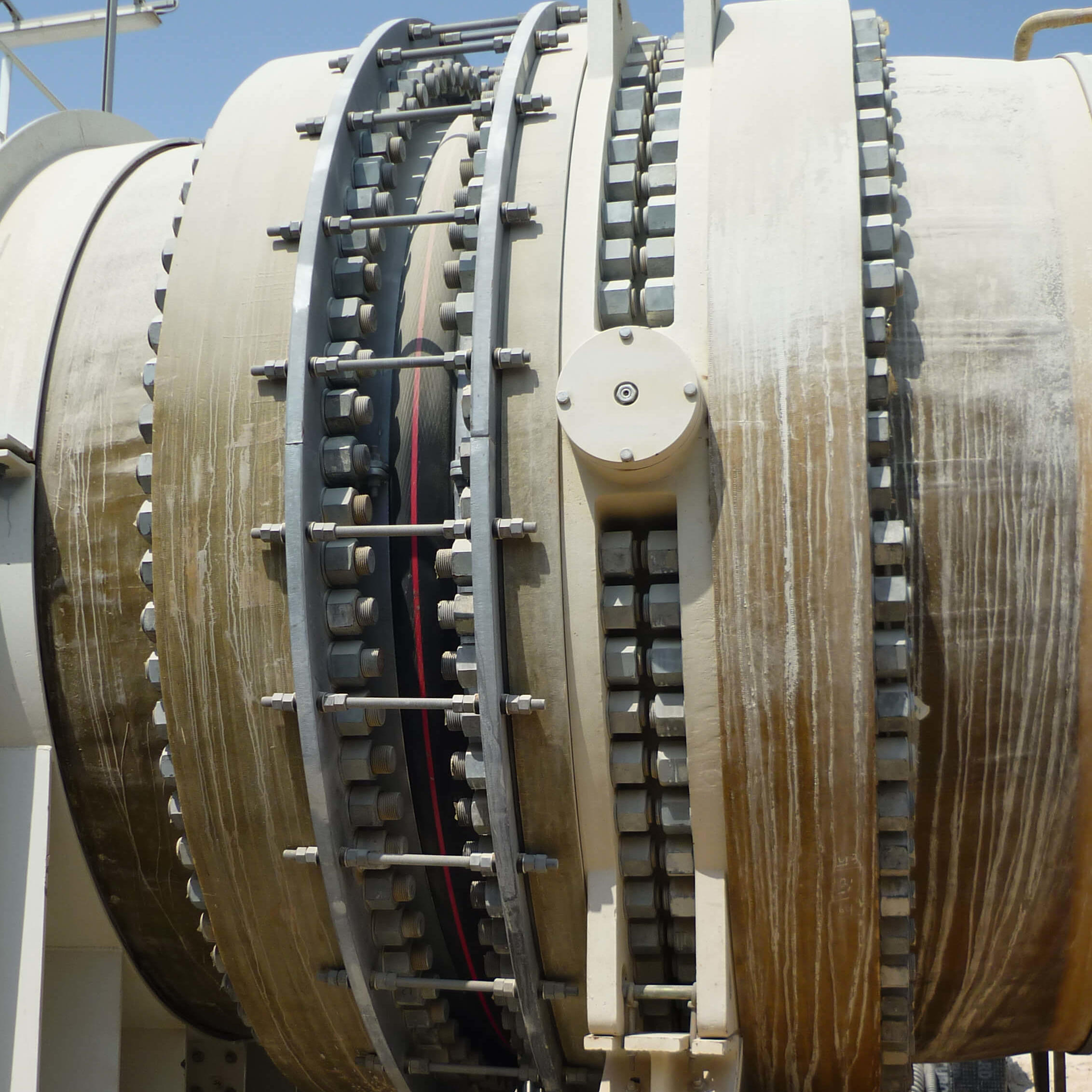

Metal expansion joints for exhaust systems

- Type FR-UN DN900

- Temperature: 600 °C

- Pressure: 500 mbar

- Movement: axial: 20 mm, lateral: 35 mm

- Application: LPG gas tanker

Energy

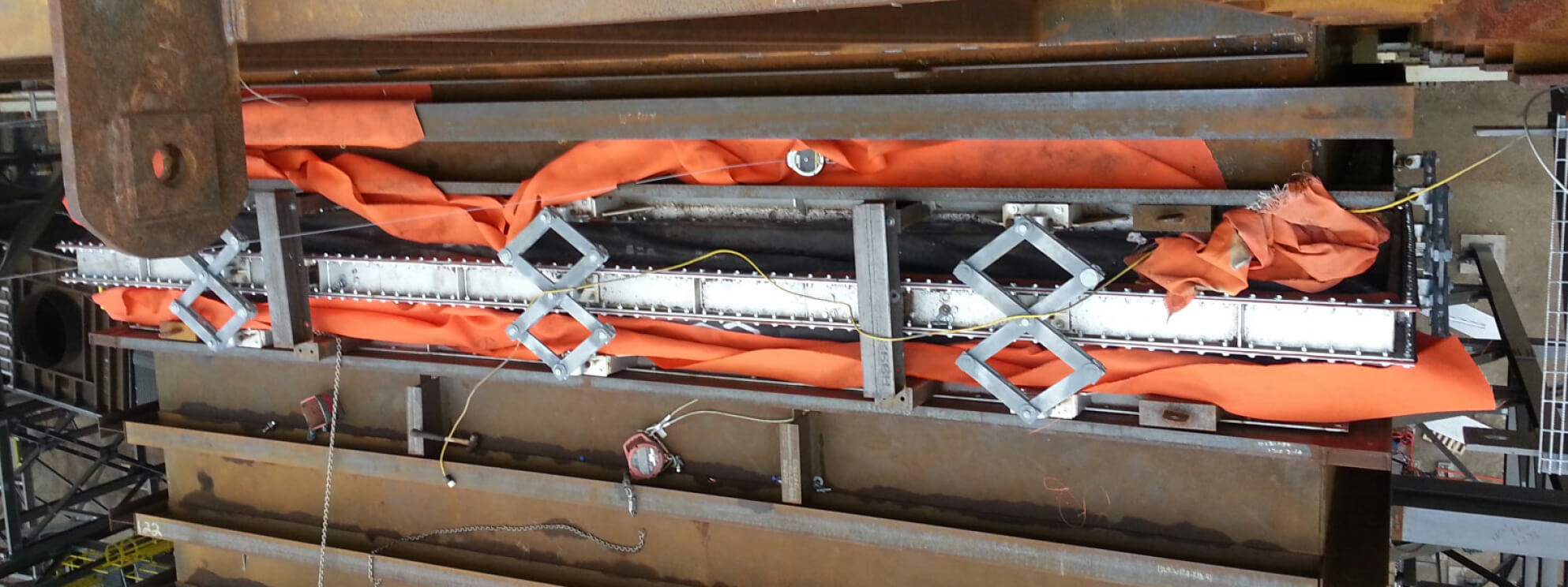

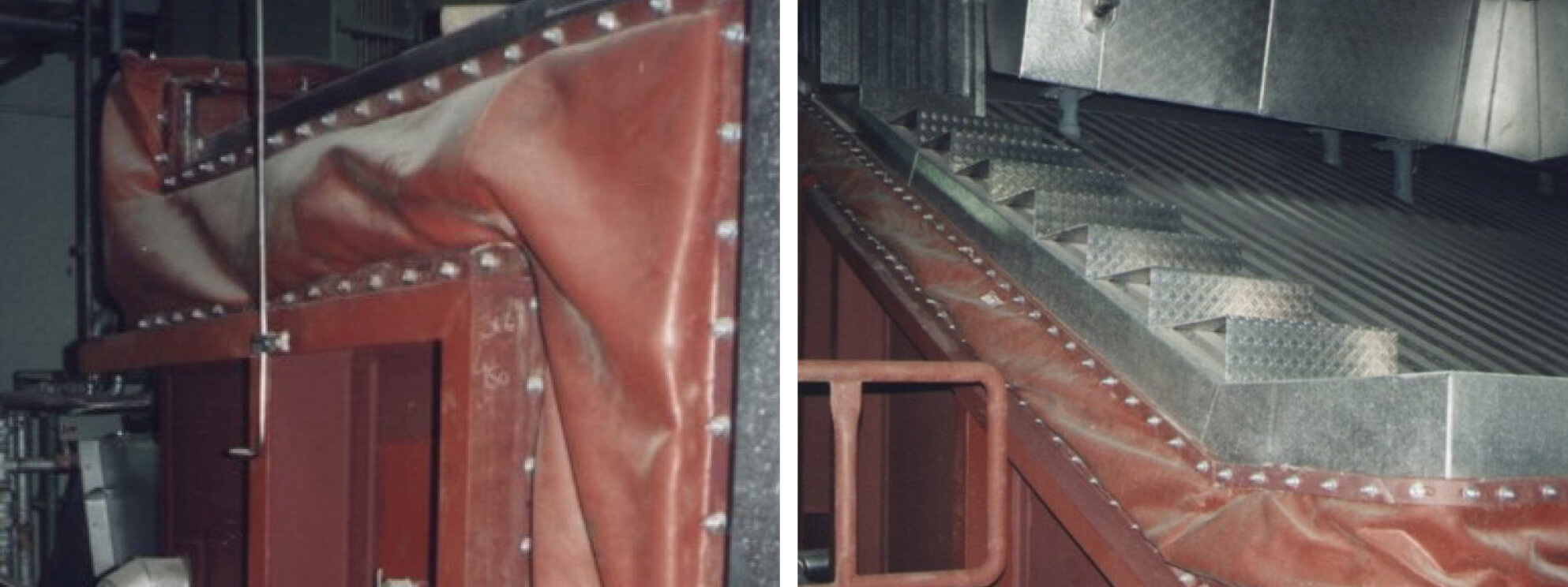

Expansion joints with pantograph control guide in exhaust gas cleaning

Expansion joints for large movements, wind loads

Expansion joints with pantograph control guide at boiler outlet

Expansion joints for large movements due to wind loads

Gas turbine exhaust system for high temperatures

The most highly stressed expansion joint in the exhaust system directly at the turbine outlet with exhaust gas temperature of max. 700 °C and an axial compression of minus 110 mm with simultaneous lateral shifting of 50 mm. The expansion joint is located directly at the junction of the outer-insulated turbine flange to the inner-insulated exhaust gas duct.

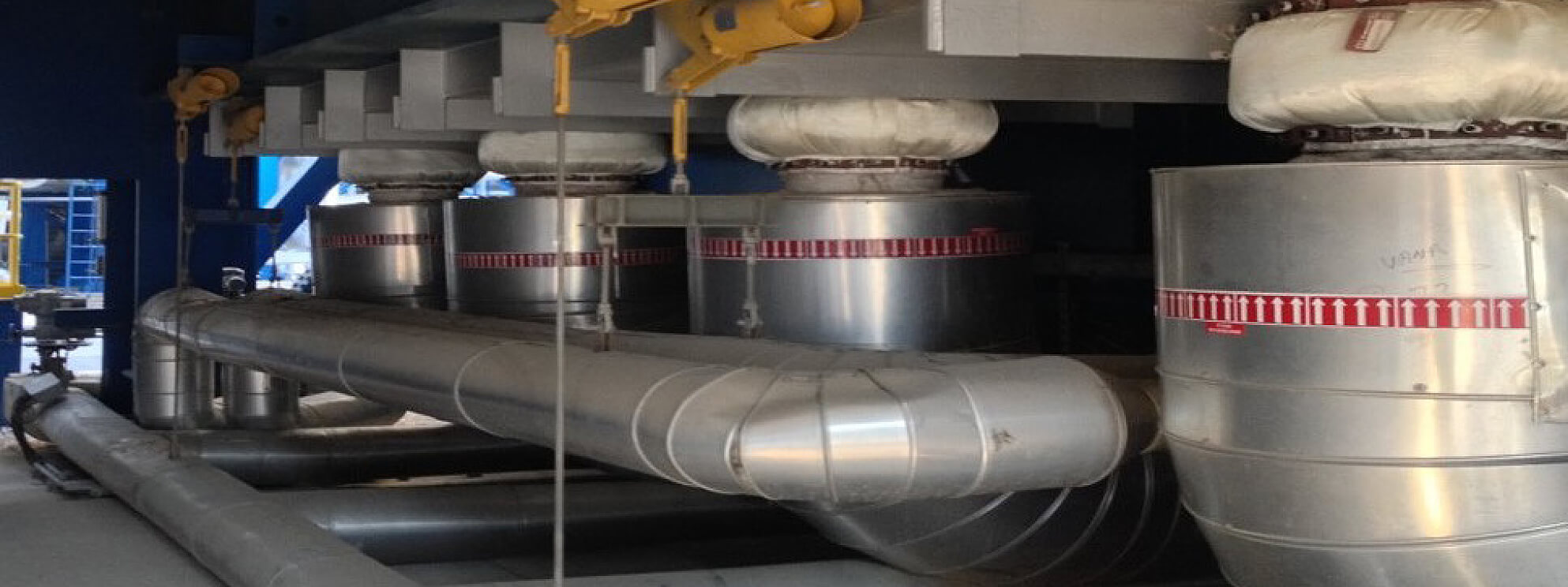

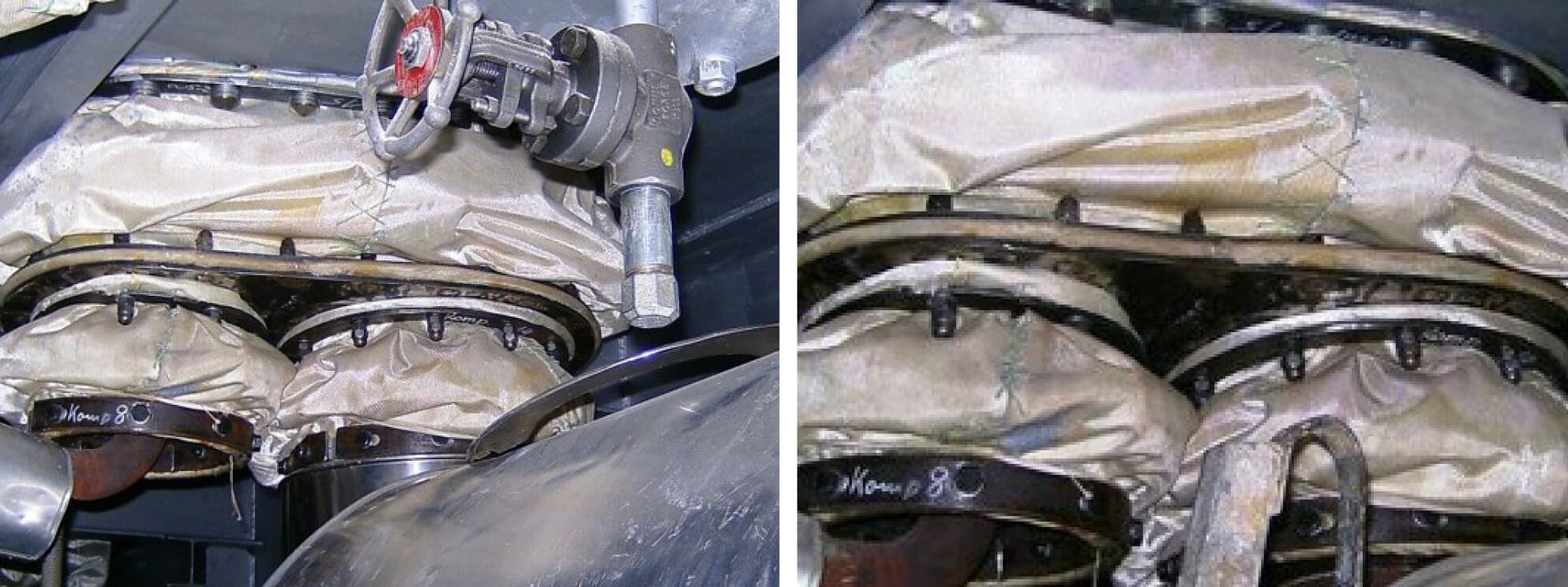

Multi-tube boiler seal at waste heat boiler of gas turbine

- Specially designed fabric/non-metallic expansion joints

Double fabric expansion joint as boiler seal for waste heat boiler of gas turbine

- Specially designed fabric/non-metallic expansion joints

Fabric expansion joint as boiler seal for waste heat boiler of gas turbine at base

Bolted connection for high temperatures at base

Fabric expansion joints as boiler seal for waste heat boiler of gas turbine

Frenzelit fabric expansion joints for high axial and different lateral movements

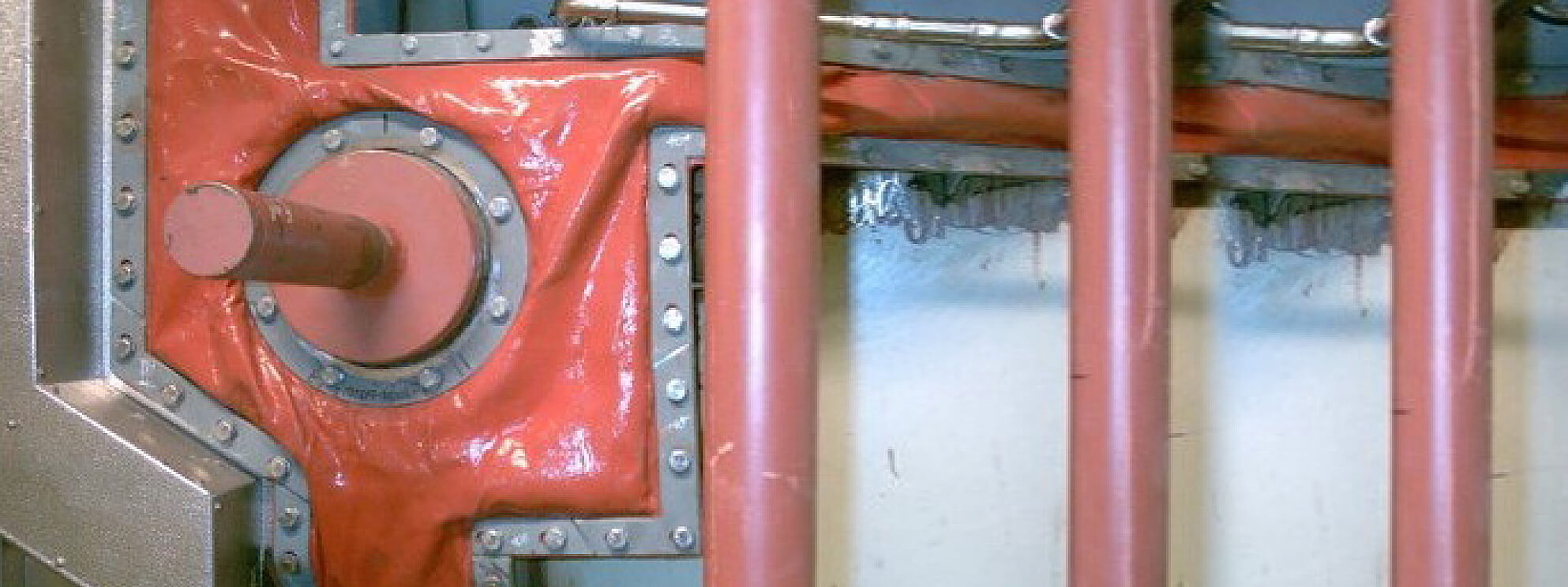

Header pipe bellow on breakthrough at incinerator boiler with chute entry

- Specially designed fabric/non-metallic expansion joints

Corner segment at incinerator boiler

- Specially designed fabric/non-metallic expansion joints

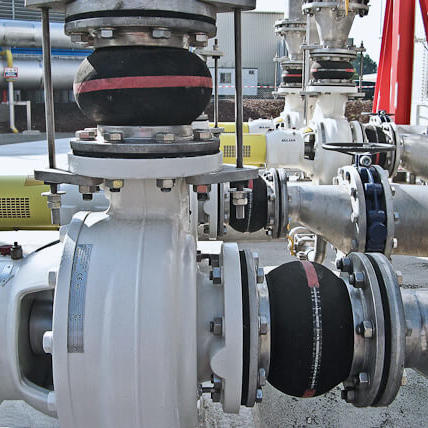

Chemical & petrochemical industry

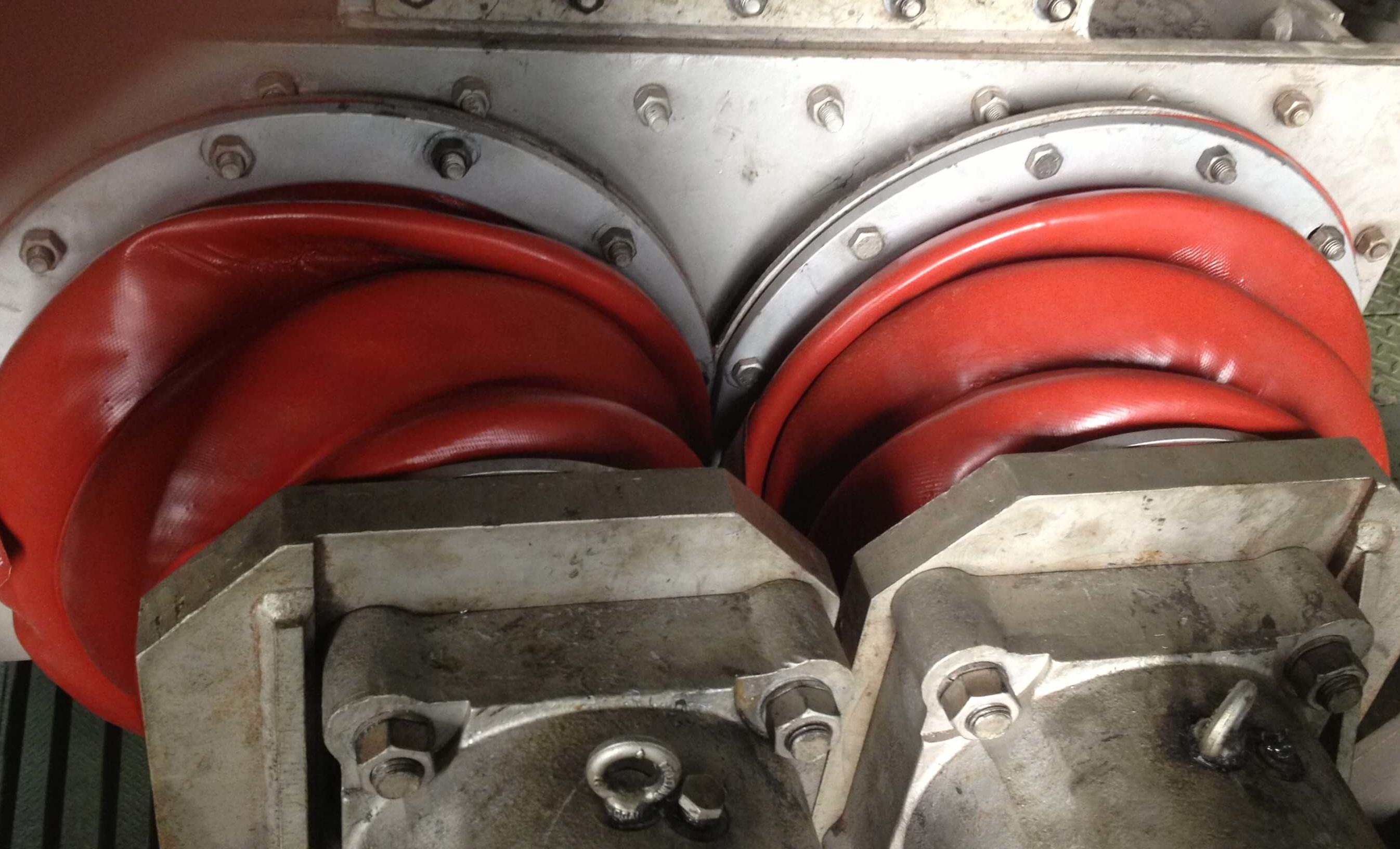

Flexible rubber expansion joints

DN 125 / 10 bar

DN 80 - 4000 / max. 2.5 bar