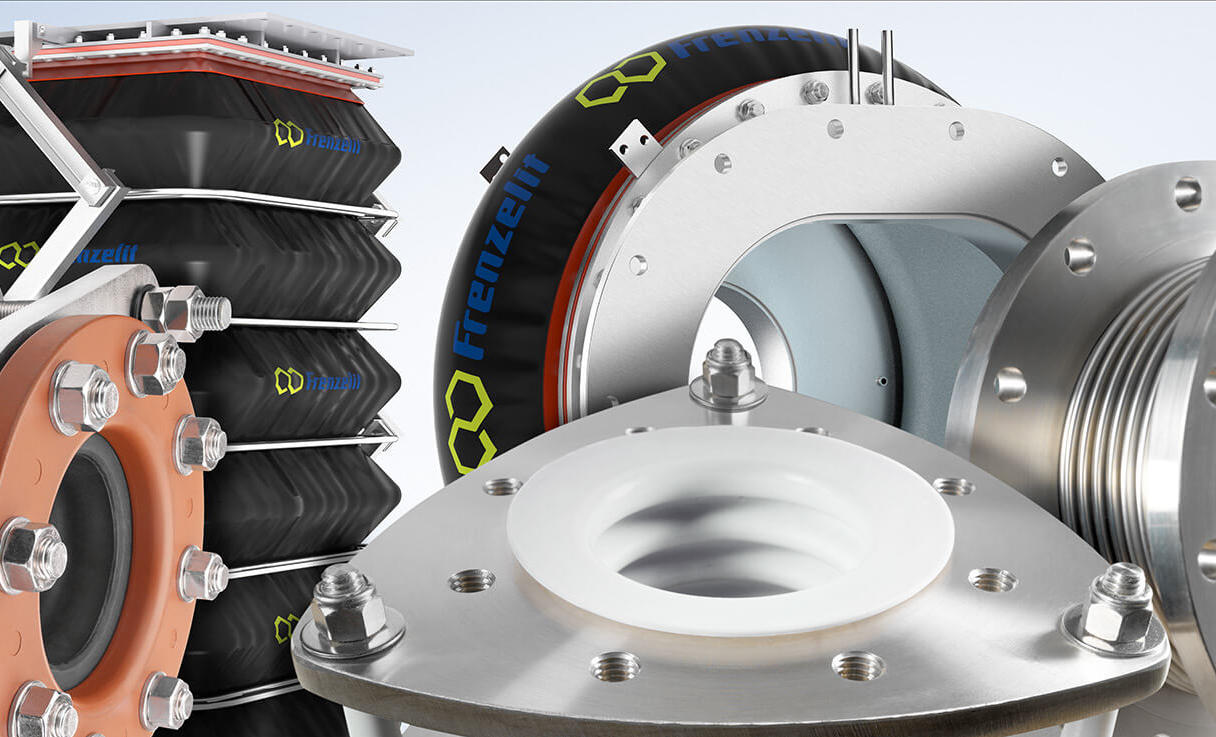

Elastomer Expansion Joints

Frenzelit elastomer expansion joints for aggressive media are made from highly flexible materials with excellent resistance. The extraordinary properties of these base materials are ideal for the very high demands in gas cleaning plants.

- Excellent mechanical stability against vibrations

- Very good resistance to deformation

- Resistance to SO2, SO3, H2SO4 and many other aggressive media

- Long-term temperature up to 204 °C depending on material

- Good low temperature resistance

- Nekal-tight in clamping and bellow area

- Installation of baffles not required

- Ideal for saturated and moist gases

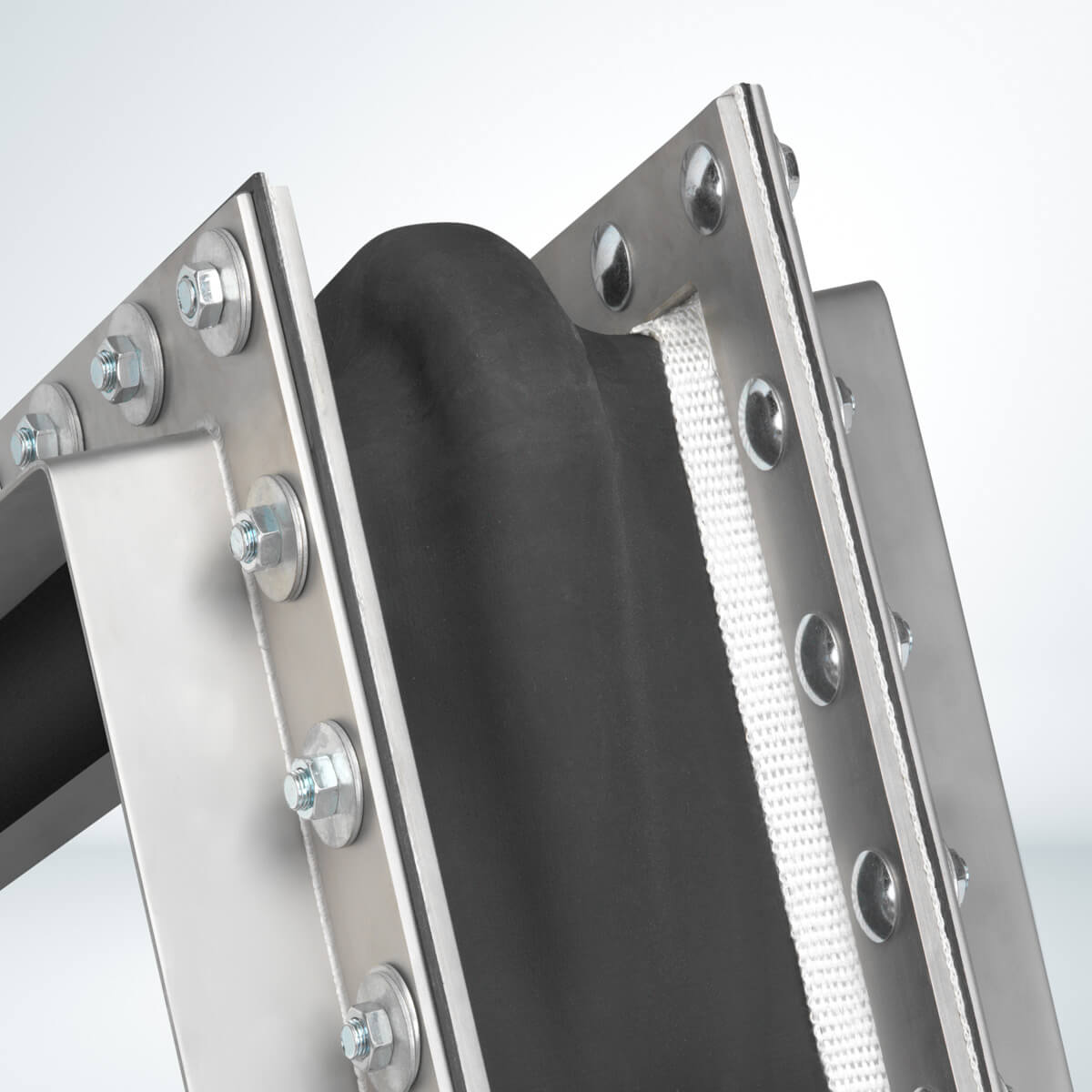

Elastomer materials<br/> The expansion joint thickness with elastomer can vary from 3.5 mm, 4.5 mm to 6 mm depending on the requirements; ideal for abrasive media with dust exposure and vibrations. Carrier fabrics made from isoGLAS®, isoTHERM® or novatex® (glass, aramid/glass-fabric blend) from our own in-house production and stainless steel mesh are vulcanized into the elastomers to provide reinforcement against extreme pressure and tensile loads. Two different inserts can be combined in expansion joints with thicknesses of 4.5 and 6 mm, depending on the requirements.

In addition to the ISO certifications, leading manufacturers of expansion joints established the Quality Association for Fabric Expansion Joints (RAL-Gütegemeinschaft). The quality assurance body develops standards for the production and use of flexible (fabric) expansion joints. These RAL GZ-719 Quality Assurance standards are published as “Technical Information” (please see documents and download area) and are recognized by the industry and inspection agencies. The members of this association are also audited for compliance with these standards on a regular basis by independent certification bodies such as TÜV. Frenzelit expansion joints meet these standards and are approved to carry the RAL quality mark. This guarantees that our customers get the best possible quality available on the market today.

- System solutions

- Application areas

- Documents and downloads

- Types

The expansion joint types, movements, temperature and pressure variations shown are only valid for the values provided in the example.

Elastomer expansion joints may have the same construction and movement absorption, but they can be designed with a different material structure for use in different application areas.

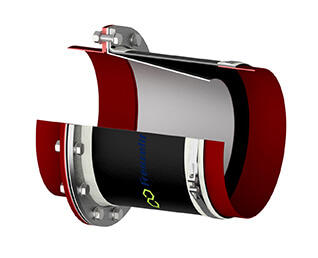

Expansion joint type 01.001 Movement from distance of pipe (AR) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 300 / 401 °F ± 2.9 psi 150 / 205 °C ± 200 mbar PTFE 600 °F ± 2.9 psi PTFE 316 °C ± 200 mbar

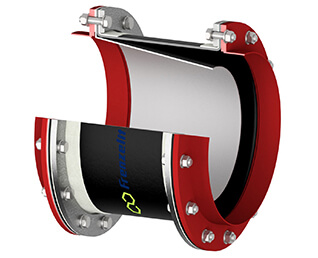

Expansion joint type 01.101 and 1.141 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 300 / 401 °F ± 2.9 psi 150 / 205 °C ± 200 mbar PTFE 600 °F ± 2.9 psi PTFE 316 °C ± 200 mbar

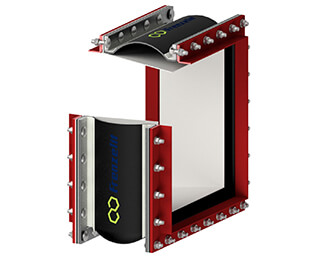

Expansion joint type 01.201 Movement from distance of pipe (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 300 / 401 °F ± 2.9 psi 150 / 205 °C ± 200 mbar PTFE 600 °F ± 2.9 psi PTFE 316 °C ± 200 mbar

Expansion joint type 01.211 Movement from distance of pipe (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 35% and lateral 15% 300 / 401 °F ± 2.9 psi 150 / 205 °C ± 200 mbar PTFE 600 °F ± 2.9 psi PTFE 316 °C ± 200 mbar

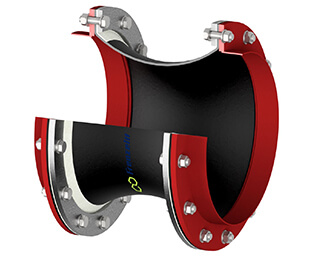

Expansion joint type 01.422 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 70% and lateral 10% 300 / 401 °F ± 2.9 psi 150 / 205 °C ± 200 mbar PTFE 600 °F ± 2.9 psi PTFE 316 °C ± 200 mbar

Expansion joint type 01.241 Movement from distance of pipe (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 40% and lateral 20% 300 / 401 °F ± 2.9 psi 150 / 205 °C ± 200 mbar PTFE 600 °F ± 2.9 psi PTFE 316 °C ± 200 mbar - Service

Service

Expansion joints must withstand loads like the system component or pipe itself absorb and additional stress, movements, oscillations or vibrations in axial and/or lateral direction – while ensuring operational safety.

You may already have a very good idea what your expansion joint should look like. Or an application that you want to further develop. A partnership with Frenzelit allows you to realize your ideas according to your system-specific requirements.

We offer you the following:

Frenzelit engineers work together with your design department to develop a technically and economically feasible solution that meets your demands. Our experts are at your disposal in all project phases to develop fabric, non-metallic and elastomer expansion joints, PTFE and multi-laminated PTFE expansion joints as well as rubber and metal expansion joints for your system. We are with you every step of the way – from planning and production to installation and maintenance – for the life of your system.Personal, on-site consulting ensures that your employees stay focused on what they do best, saves valuable resources and gets you the results you need faster. We develop, design or optimize expansion joints in collaboration with your team based on your specifications – so you can rest assured that they will continue to meet tomorrow’s demands. That’s why our motto is “creating hightech solutions”.