novaform® FDV

Dispenser gaskets

Dispenser gaskets

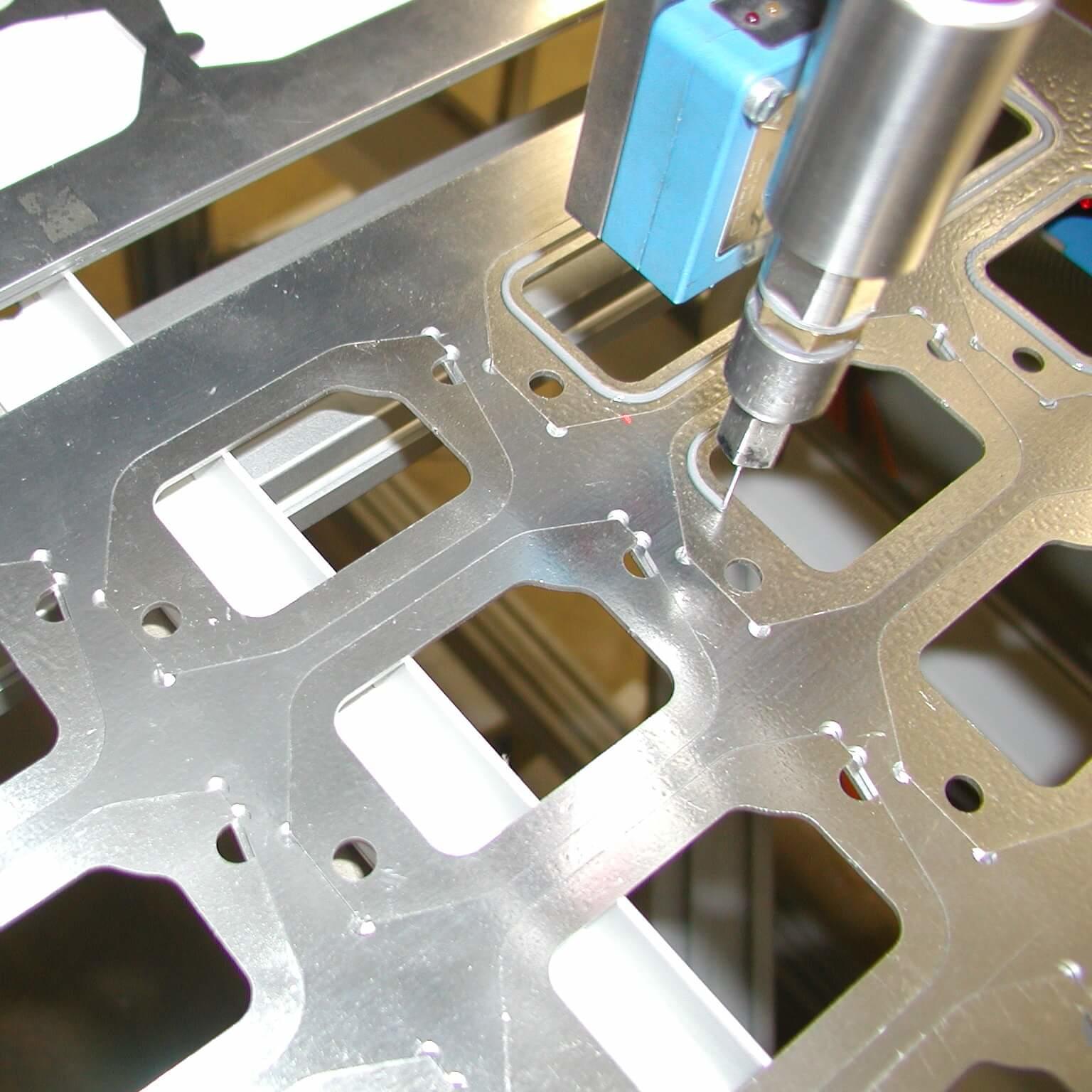

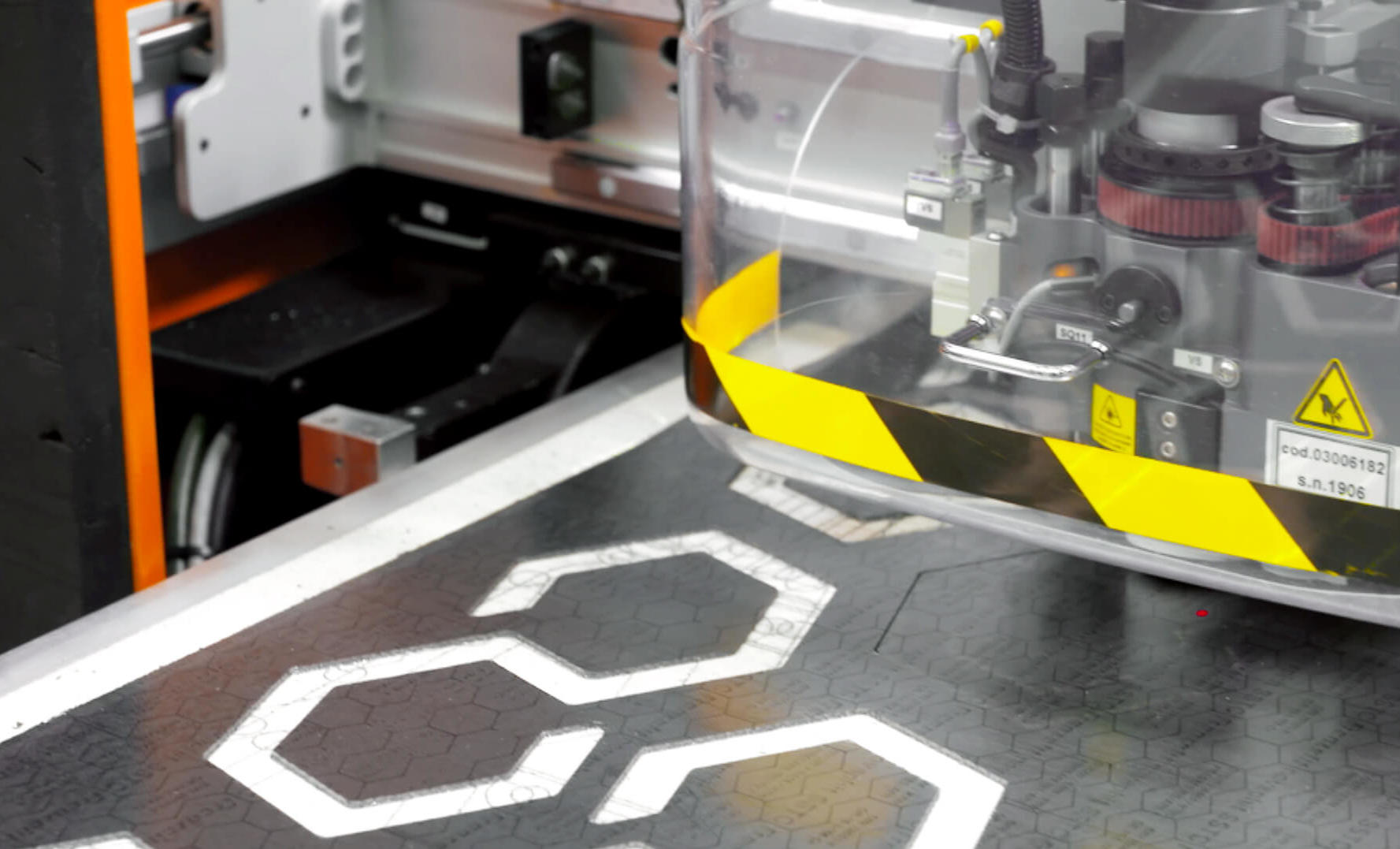

novaform® FDV gasket systems are made with dispenser technology. The dispenser creates a sealing bead in a defined position. The specially developed dispenser method creates a dimensionally stable, geometrically uniform sealing element.

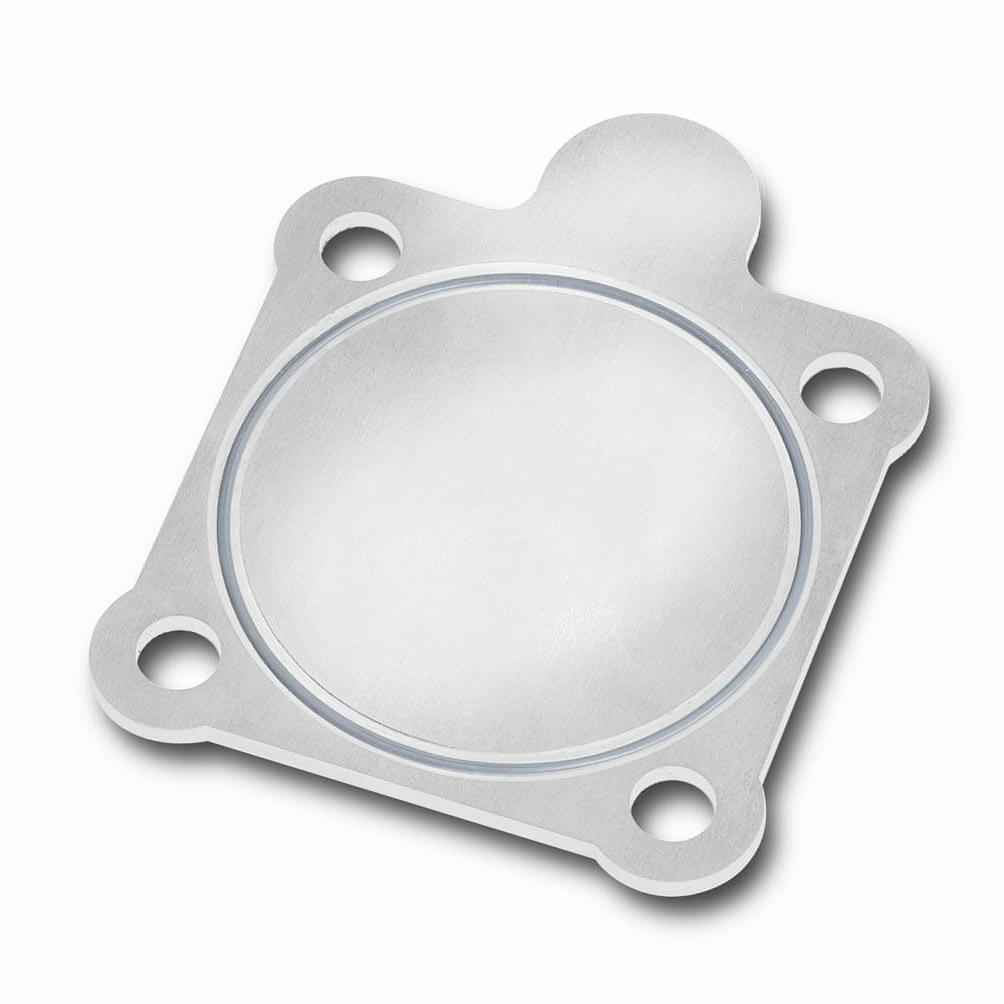

The sealing bead consists of either a non-corrosive curing silicone or of fluorine silicone for improved media resistance. The sealing bead and groove geometry are precisely coordinated to match. In addition to conventional applications as a gasket in off-load contact, the sealing bead can also be applied on components without groove or step.

Their very good adaptability and temperature & media resistance make gasket systems with novaform® FDV permanently dustproof and watertight (protection class IP6K9K according to ISO 20653), which is why they are already being used more frequently in e-mobility applications such as in:

- Battery housings

- Charging systems

- Distribution systems

Gasket in off-load contact dispenser gasket

novaform® FDV seals in off-load contact. The components are tightened “en bloc” touching each other. The elastomer creates a permanent seal in the gasket system thanks to inner restoring forces (O-ring properties) and is free from additional mechanical loads.