novapress®

Elastomer-bonded fiber gaskets

Future-oriented fiber gaskets

The novapress® product family represents the latest technology in fiber-based gasket sheets. The use of the latest process technology and a process control system for the entire manufacturing process guarantees consistent quality at the highest level – made in Germany.

novapress® is a group of elastomer-bonded gasket materials based on high-quality aramid fibers and special functional fillers. novapress® products are the standard in flat gasket applications and cover nearly all conventional applications; however, each product has special properties that make it ideal for use in specific applications.

Whether it’s innovative materials or gasket solutions that have been used successfully for many years – the novapress® product line offers you the right gasket material for countless applications.

The pioneering fiber gasket for Industry 4.0

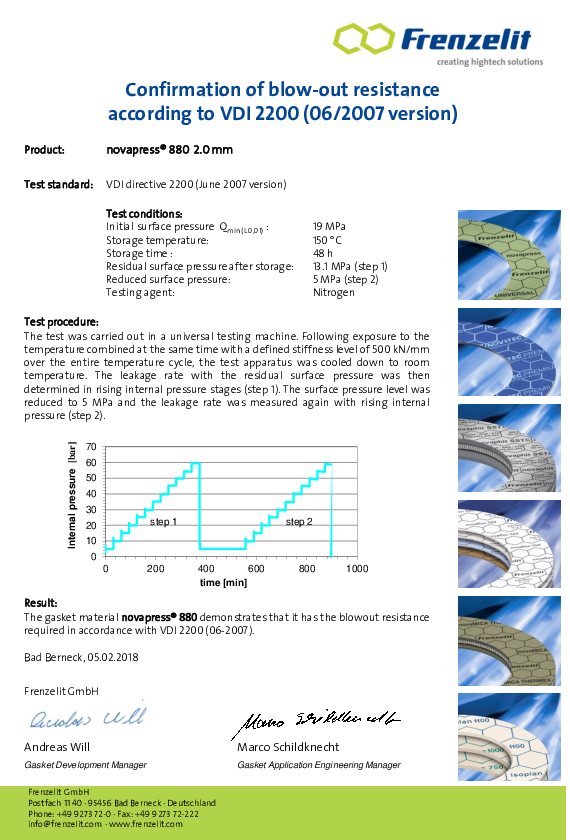

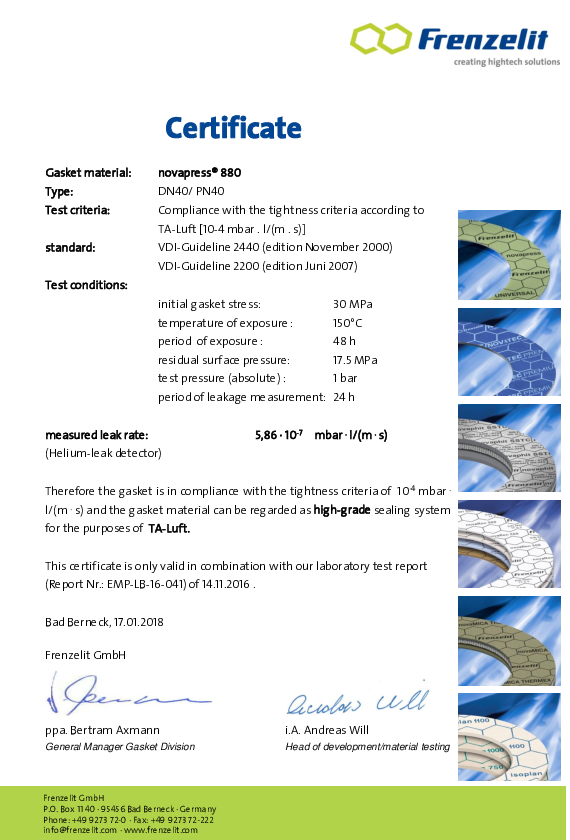

novapress® 880 combines excellent adaptability to flange unevenness with outstanding mechanical stability. Thus it complies reliably with the sealing category demanded by the VDI directive 2290 and TA Luft even in case of low surface pressure levels – whether or not an inner eyelet is applied. Thanks to its outstanding gasket parameters according to DIN EN 13555 it is possible to achieve technically effective gasket designs for flange calculations according to DIN EN 1591-1, which also include all system-related tightening tolerances.

As the first soft gasket for Industry 4.0, novapress® 880 has innovative Gasket Code Technology standard, which ensures reliable and unique identification of the material – including the production period – from even the smallest gasket dimensions.

Key properties of novapress® 880 at a glance:

Approx. 3x higher adaptability compared to conventional fiber gaskets

High mechanical stability even under temperature stress

Exceptional chemical resistance and very universal use

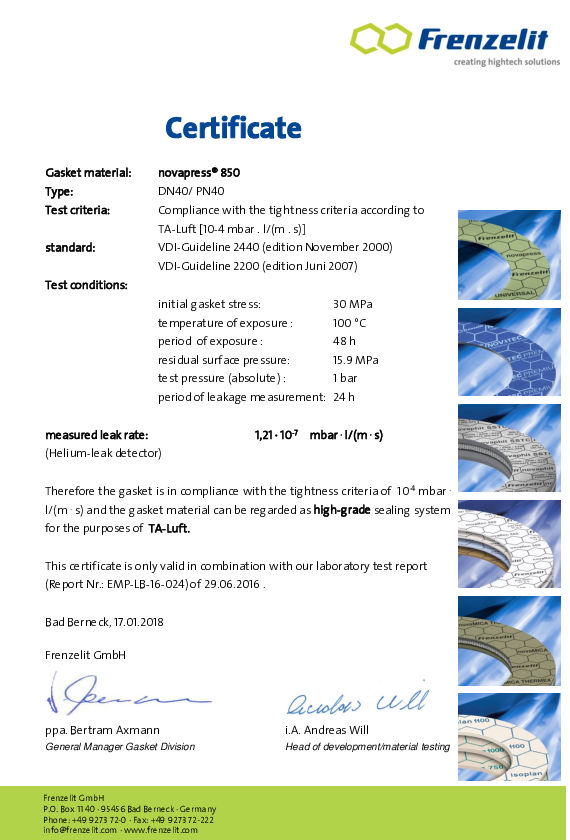

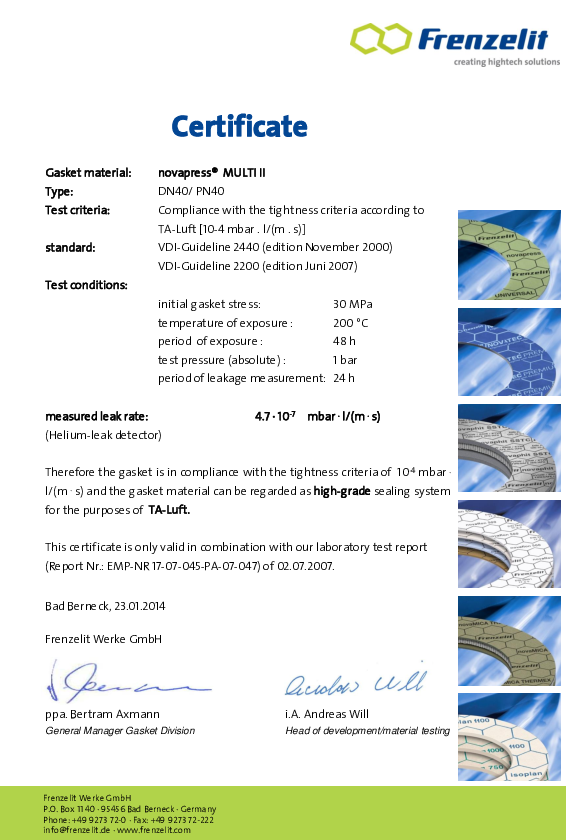

High-quality in terms of TA Luft

Nearly identical properties according to DIN EN 13555 – with or without inner eyelet

* Note on PFAS: The optional or standard PTFE surface coating of the novapress® product series can be replaced by PFAS-free surface coatings from our product range on request.

Brochure, technical data sheet and characteristic values

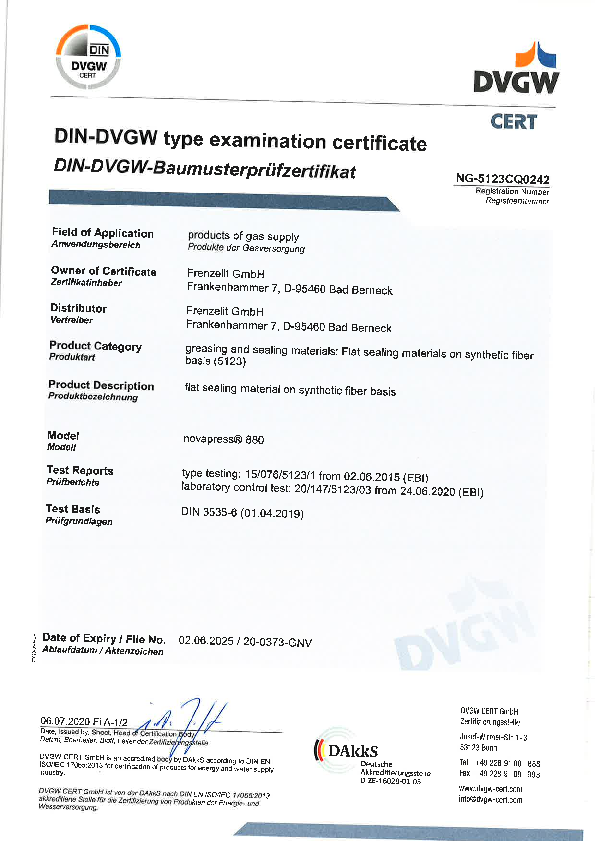

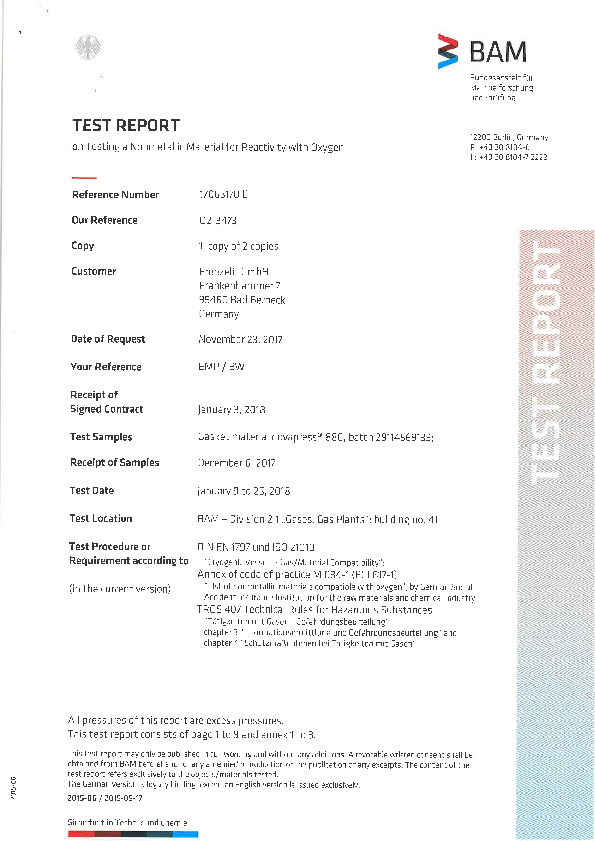

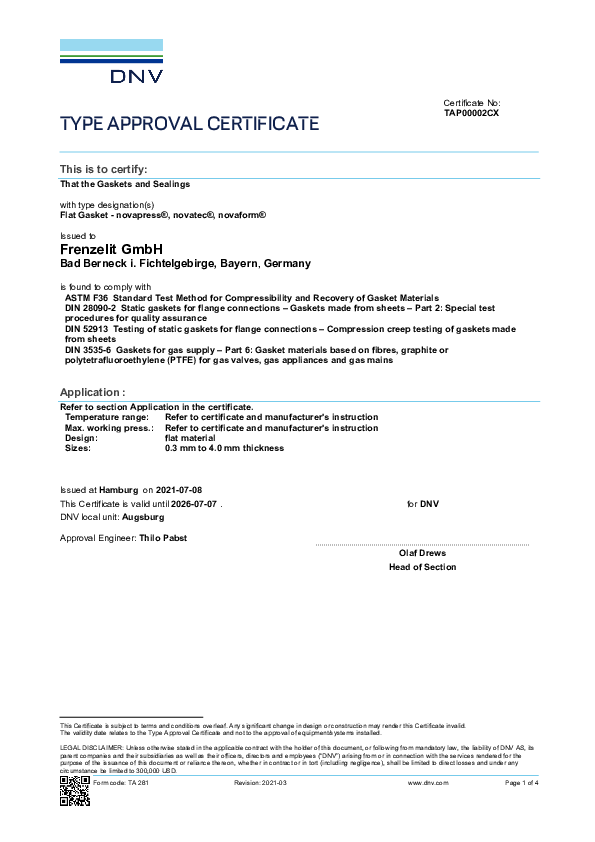

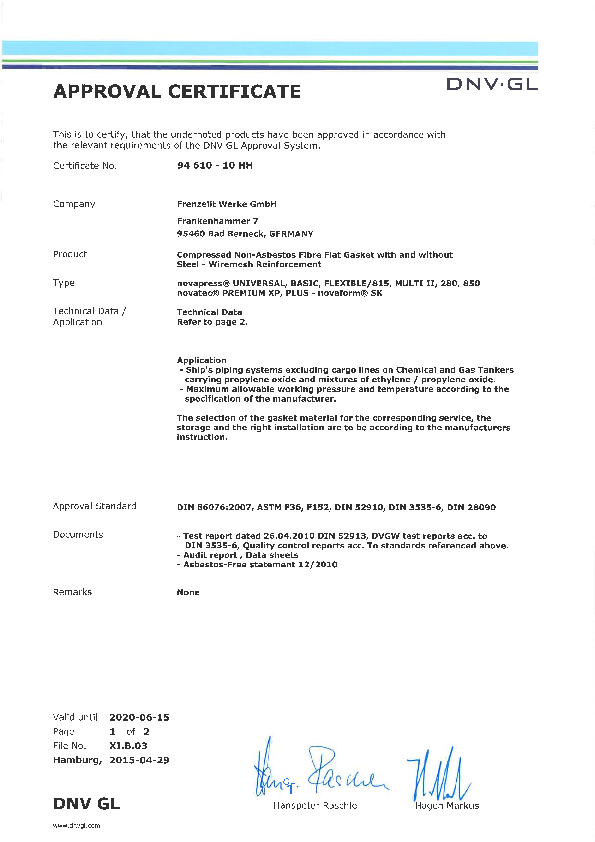

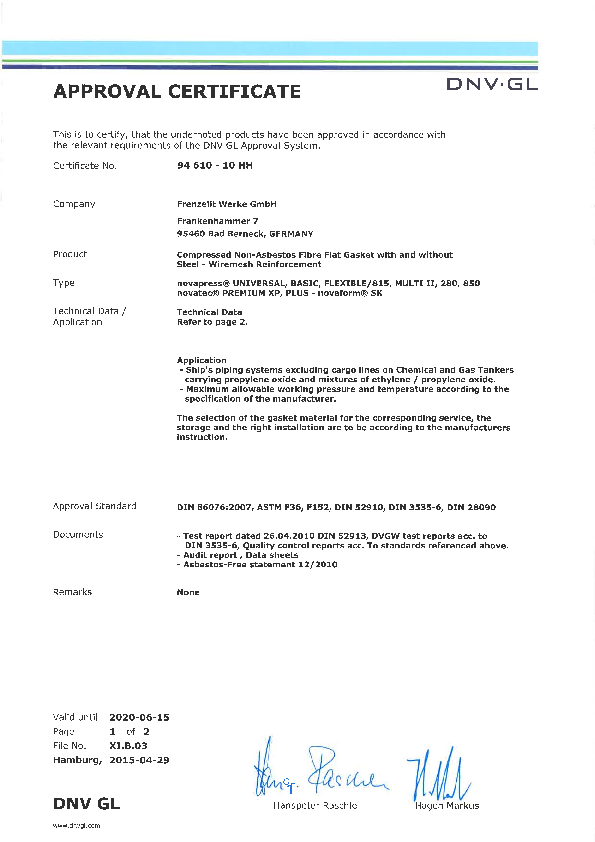

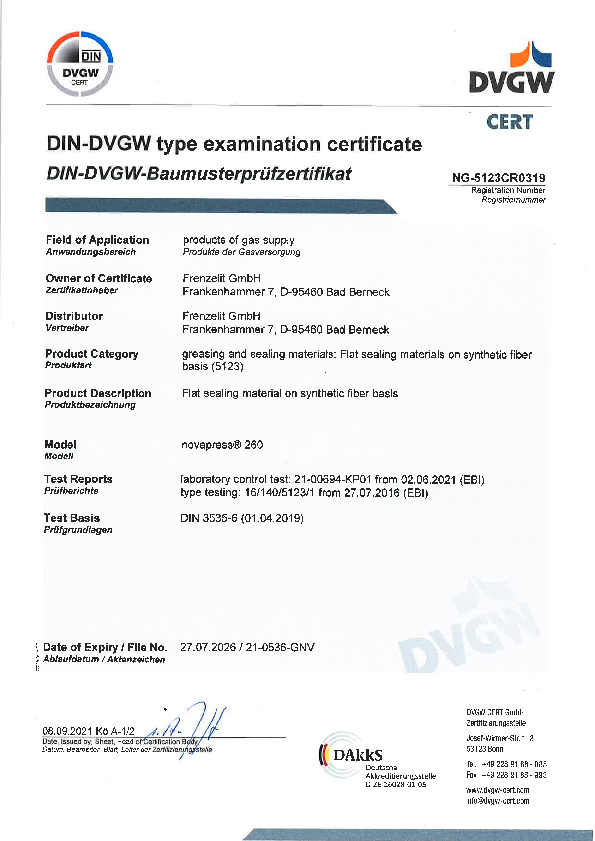

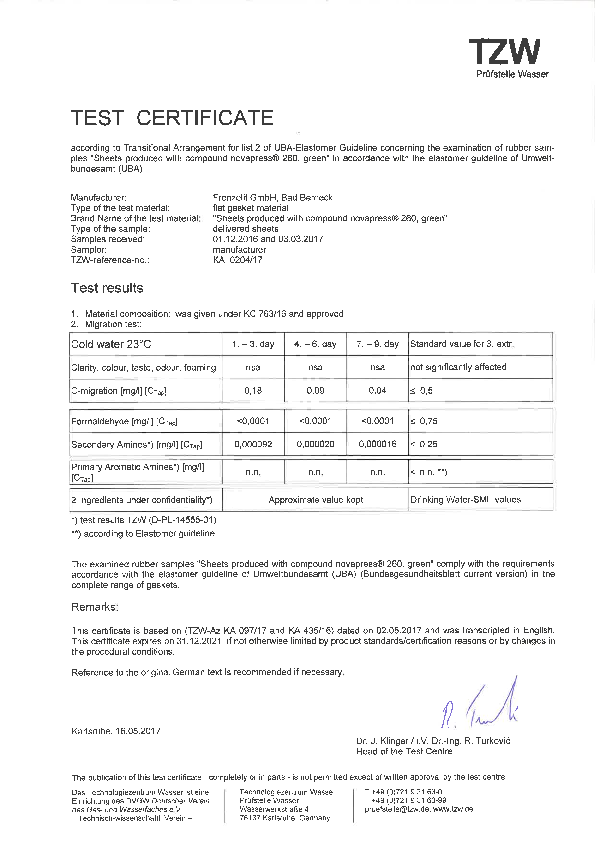

Certifications, approvals and tests:

The perfect symbiosis between fiber and elastomer

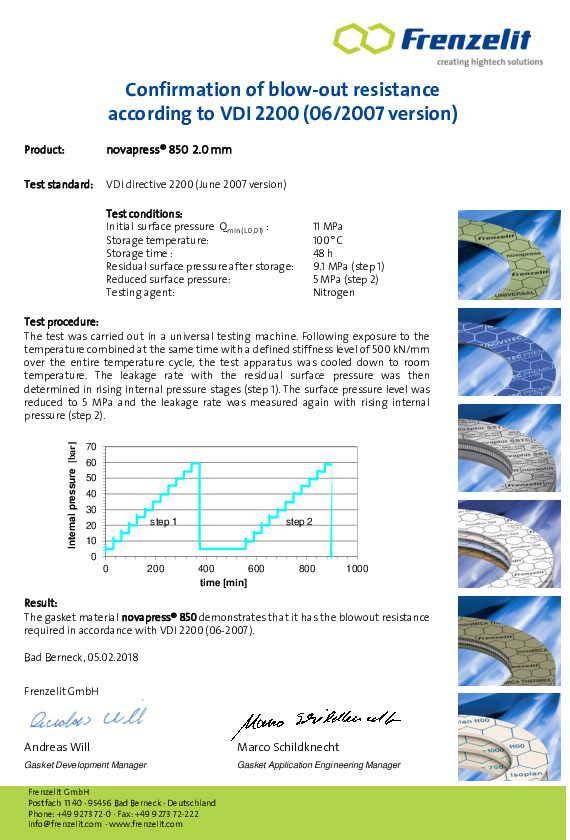

novapress® 850 (also known as novaform® 2300) offers a unique combination of the positive properties fiber and elastomer gaskets:

- Excellent adaptability – almost like an elastomer

- Mechanical stability – like conventional fiber gaskets

This enables novapress® 850 to cover applications for which neither rubber nor conventional fiber gaskets are ideal, making it the perfect solution for a variety of applications such as:

- Easily deformed and/or non-rigid structural parts

- Components with inconsistently distributed surface pressure due to screws spaced at large intervals

- Lid or housing seals for gears, pumps, etc.

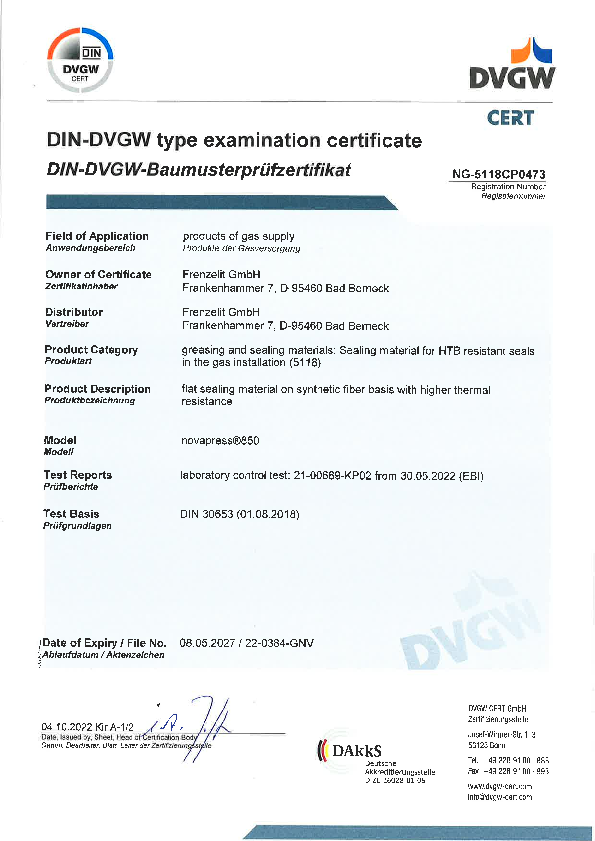

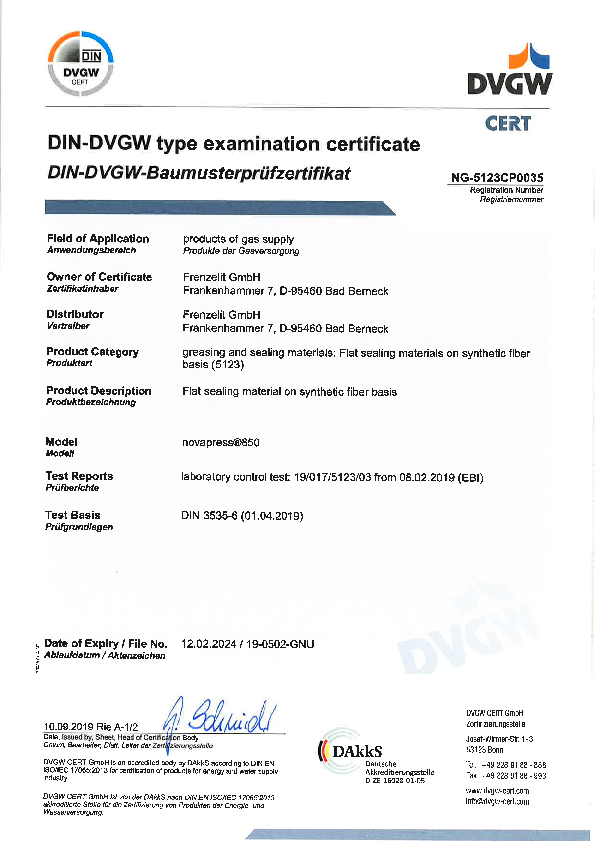

In addition, novapress® 850 has a number of approvals that make the material ideal for use in the following applications:

- Gas supply (DVGW, VP 401)

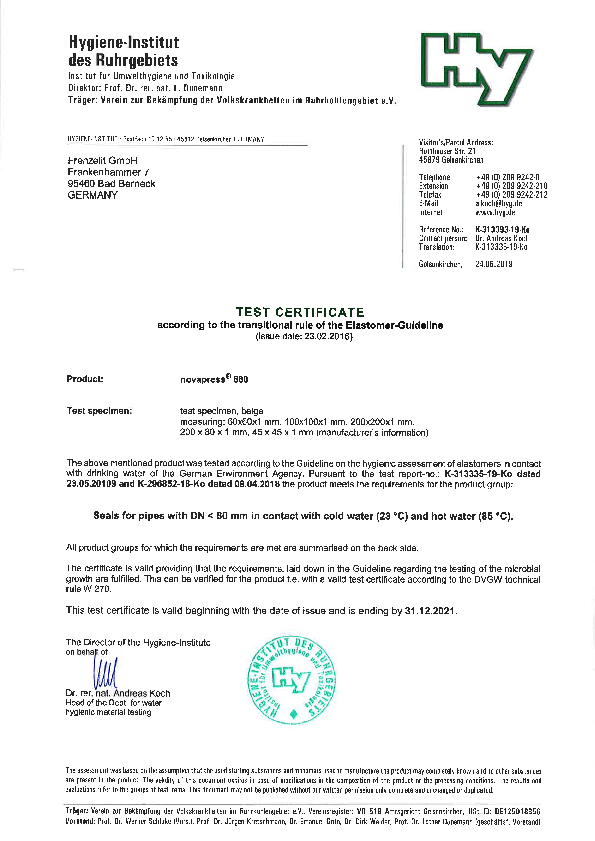

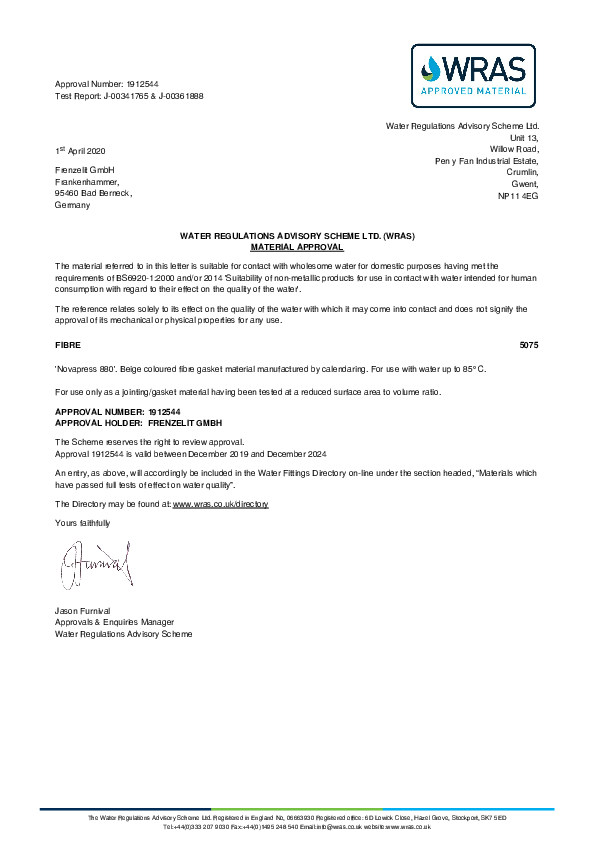

- Water supply (drinking water approval in accordance with elastomer guideline, W 270)

- Food industry (FDA, EC 1935/2004)

Brochure, technical data sheet and characteristic values

Certifications, approvals and tests:

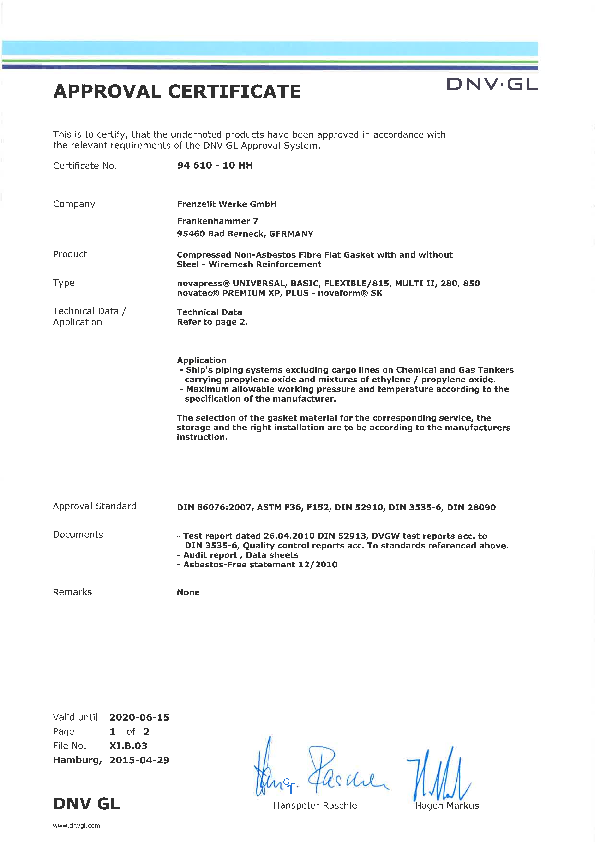

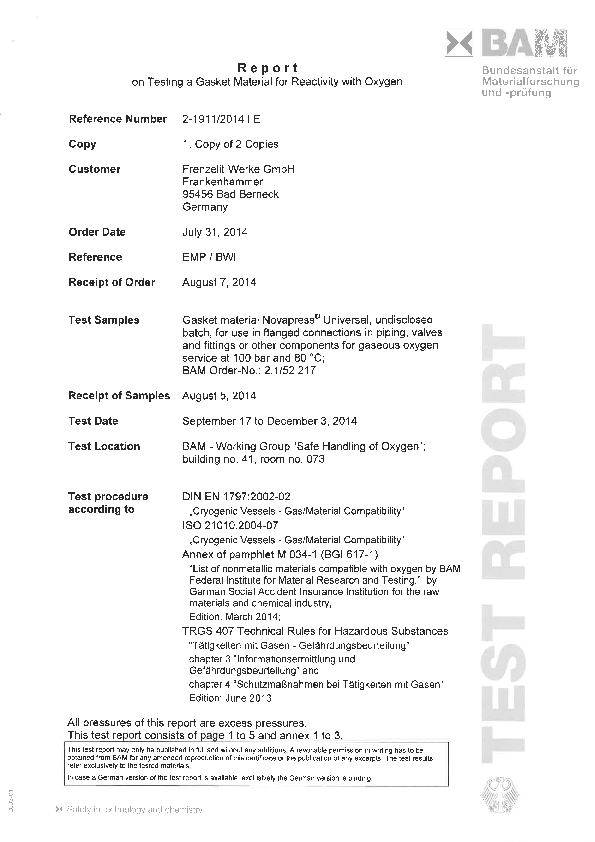

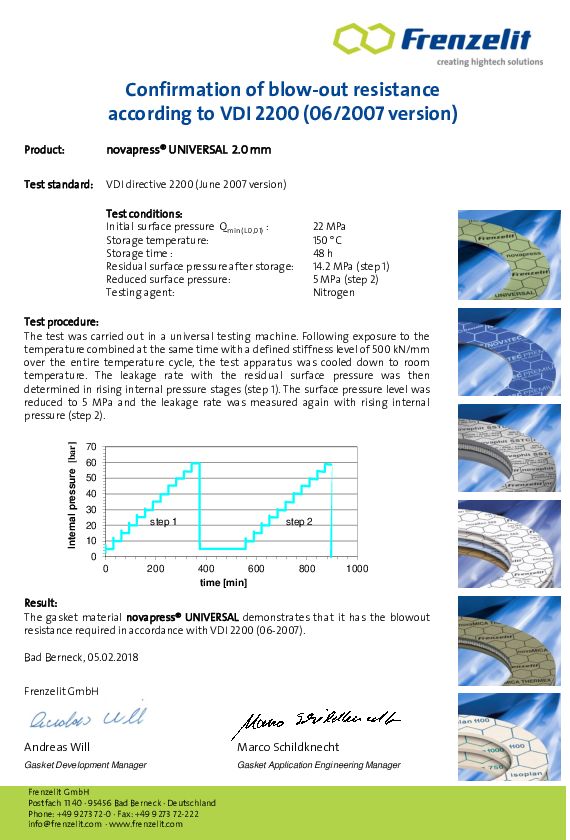

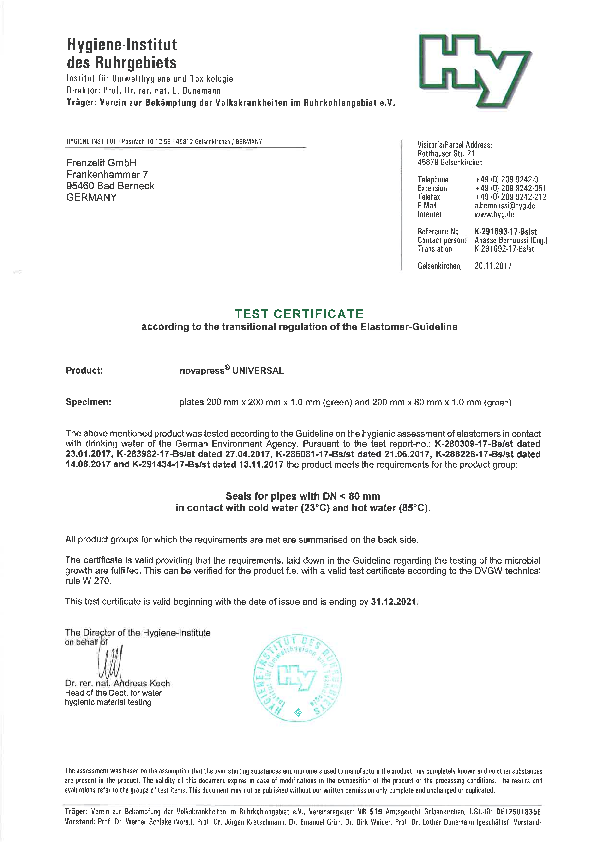

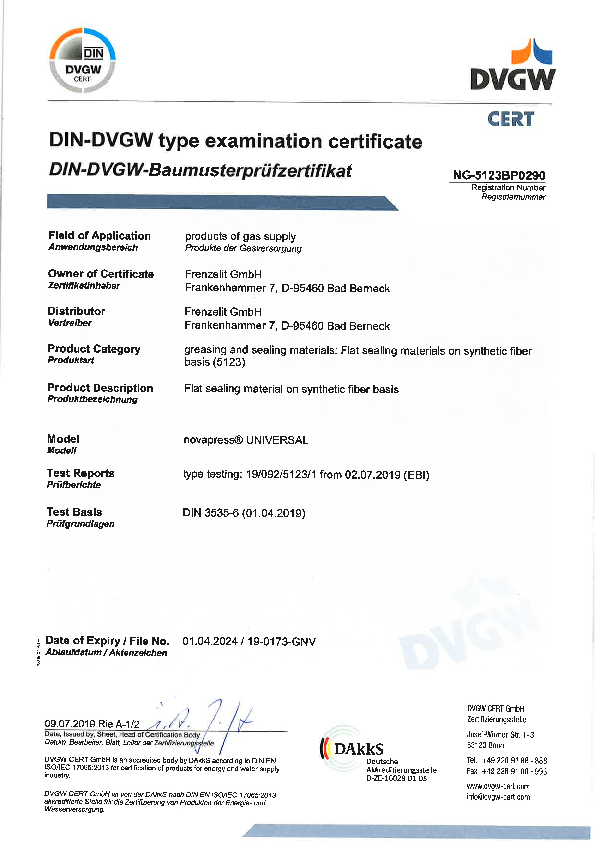

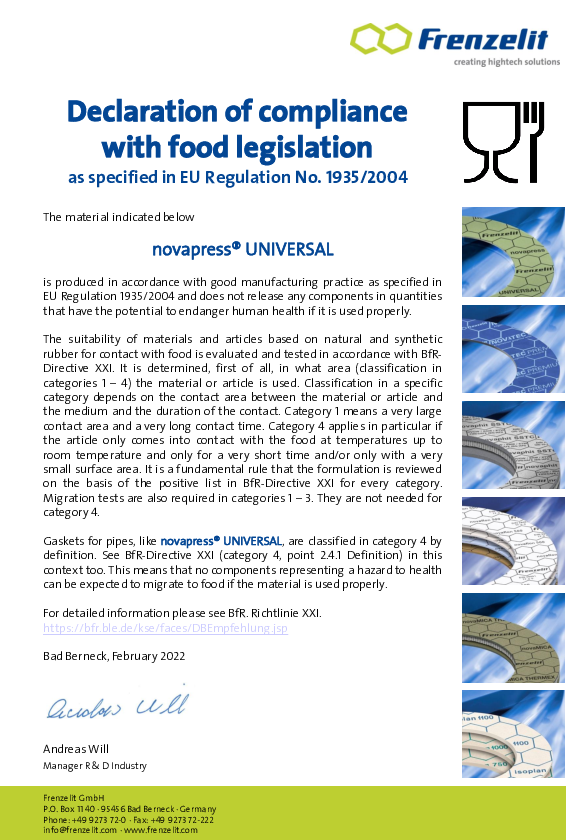

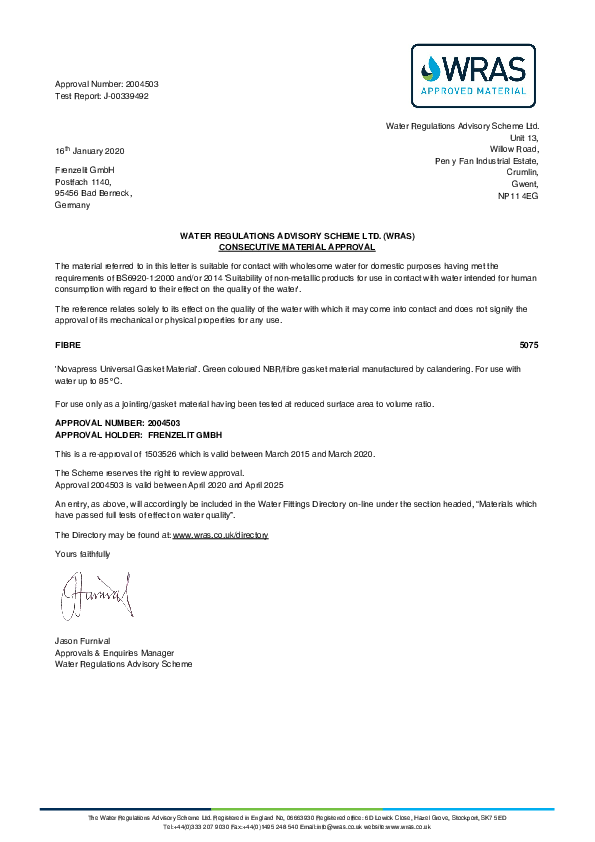

The reliable all-rounder

novapress® UNIVERSAL is the standard choice for green gaskets and has been used reliably for decades in a number of different applications. This gasket also easily satisfies higher technical requirements – well into the temperature range limit – and even more demanding gaseous and liquid media are not a problem.

Key properties of novapress® UNIVERSAL at a glance:

Extreme mechanical robustness

Exceptional chemical resistance

High-quality in terms of TA Luft

* Note on PFAS: The optional or standard PTFE surface coating of the novapress® product series can be replaced by PFAS-free surface coatings from our product range on request.

Brochure, technical data sheet and characteristic values

Certifications, approvals and tests:

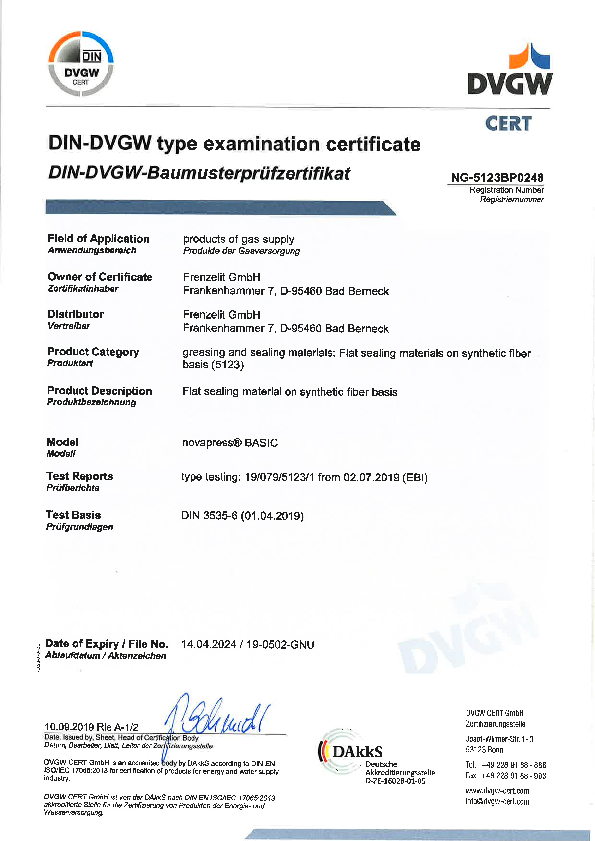

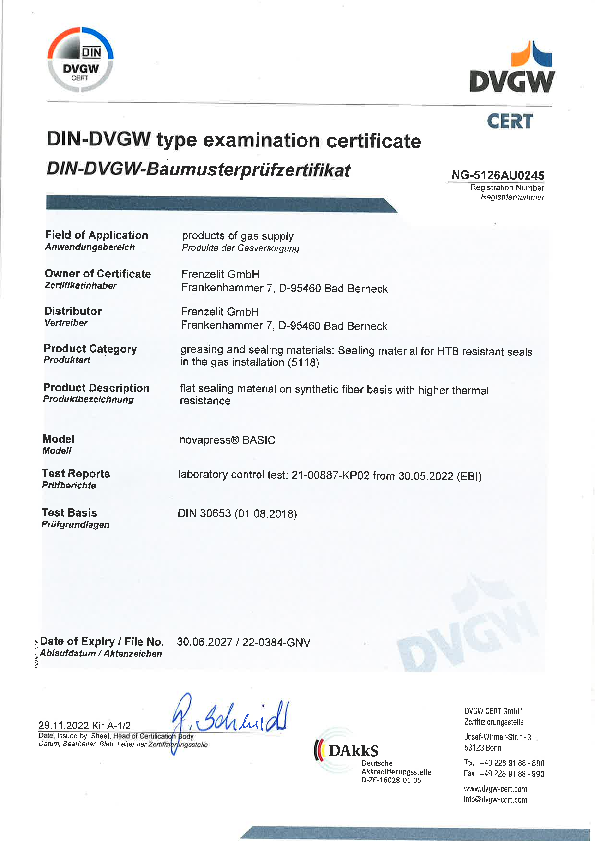

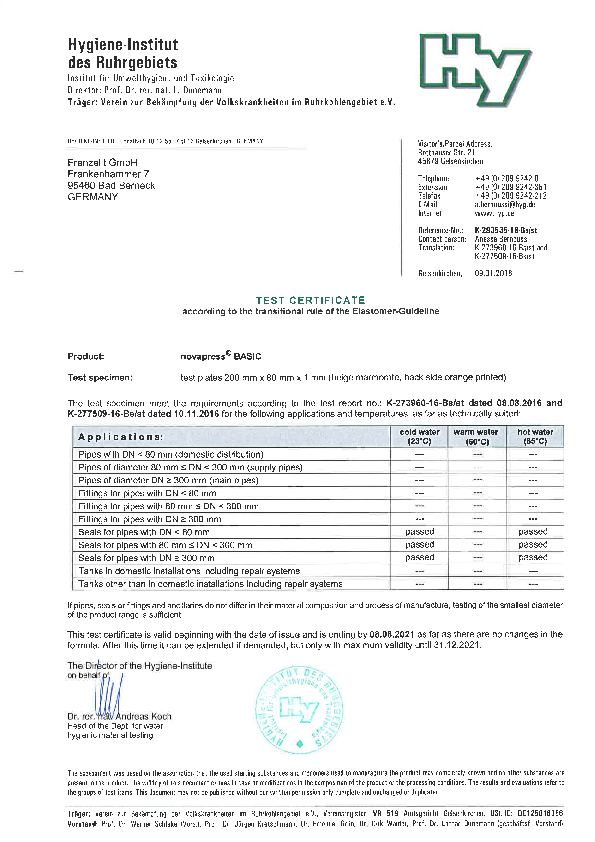

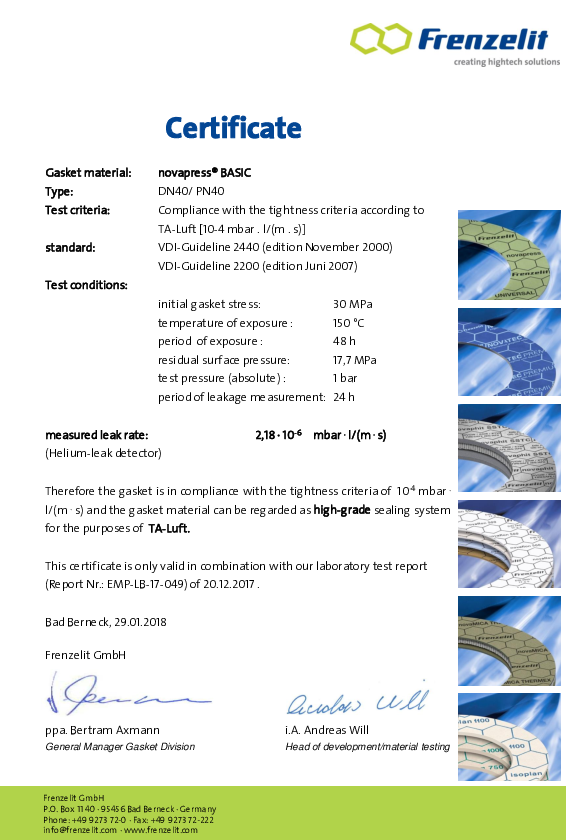

Excellent standard for a wide range of applications

novapress® BASIC is an excellent standard material for use in medium pressure and temperature ranges. The balanced composition gives the material the following special properties:

Good media resistance and residual stress

Low gas leakage

For decades, novapress® BASIC has proven itself effective in countless applications such as mechanical engineering, plant engineering and shipbuilding as well as in pipes for gas and water supply in the food industry.

Brochure, technical data sheet and characteristic values

Certifications, approvals and tests:

Optimized steam gasket

After the ban on asbestos, novapress® MULTI II was considered the first viable solution for steam-based applications and has undergone continuous further development since, making this gasket an absolutely up-to-date solution.

Its graphite components make novapress® MULTI II the perfect choice for:

Steam or hot oil

Bolted connections with torsional stress

Higher temperature loads

Use under changing loads

Also available with stainless steel mesh reinforcement on request under the name novapress® MULTI II EG.

Brochure, technical data sheet and characteristic values

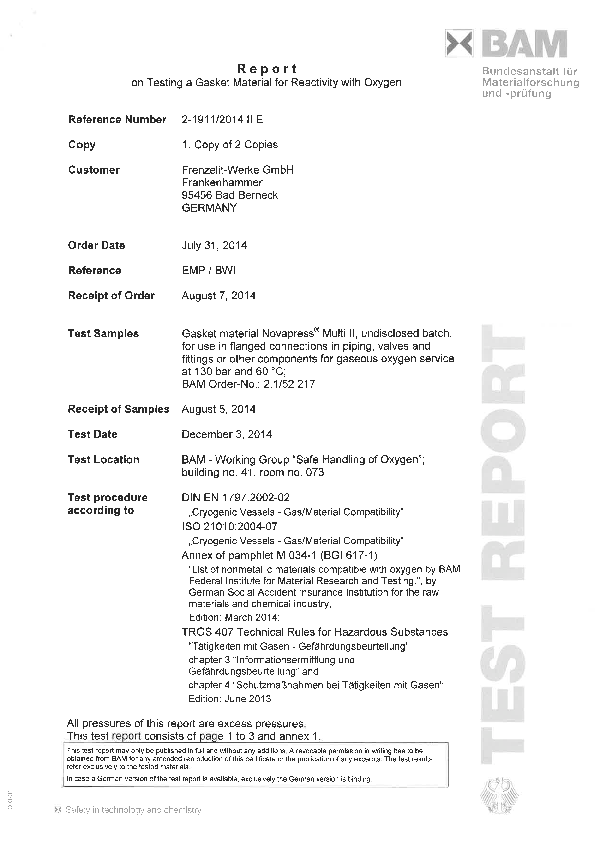

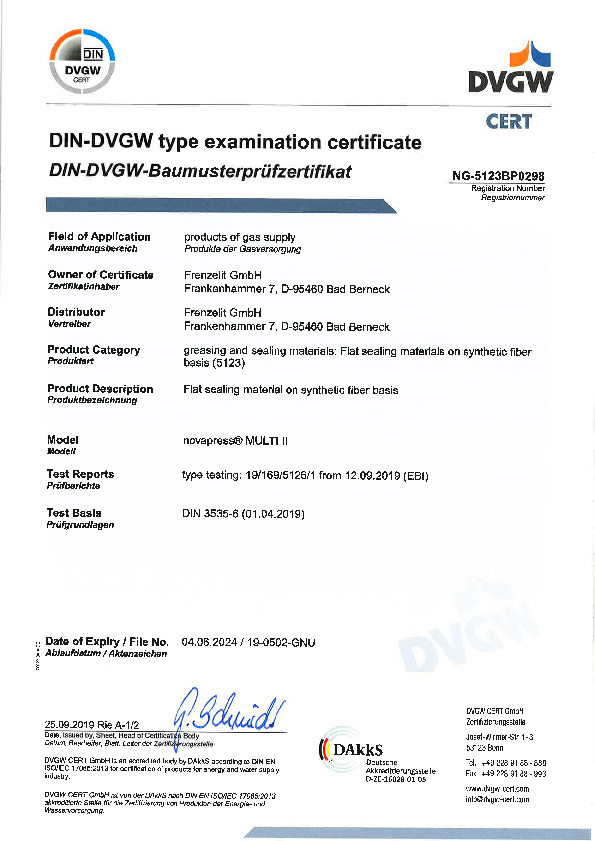

Certifications, approvals and tests:

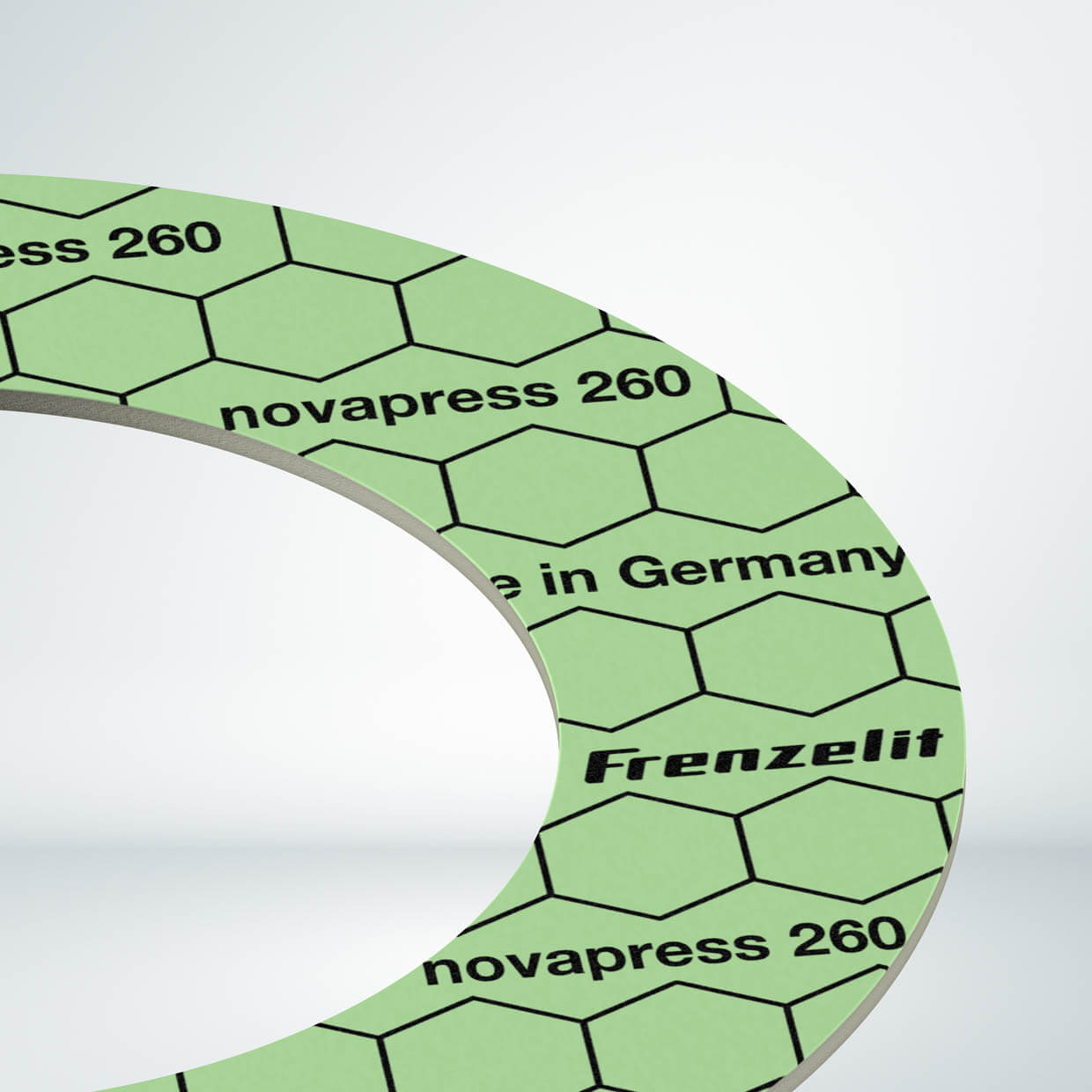

High-quality standard for basic applications

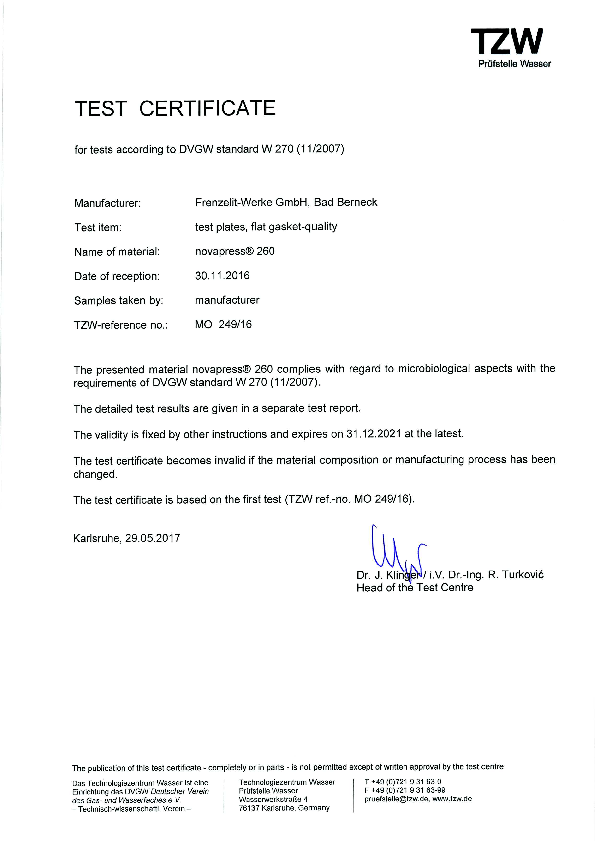

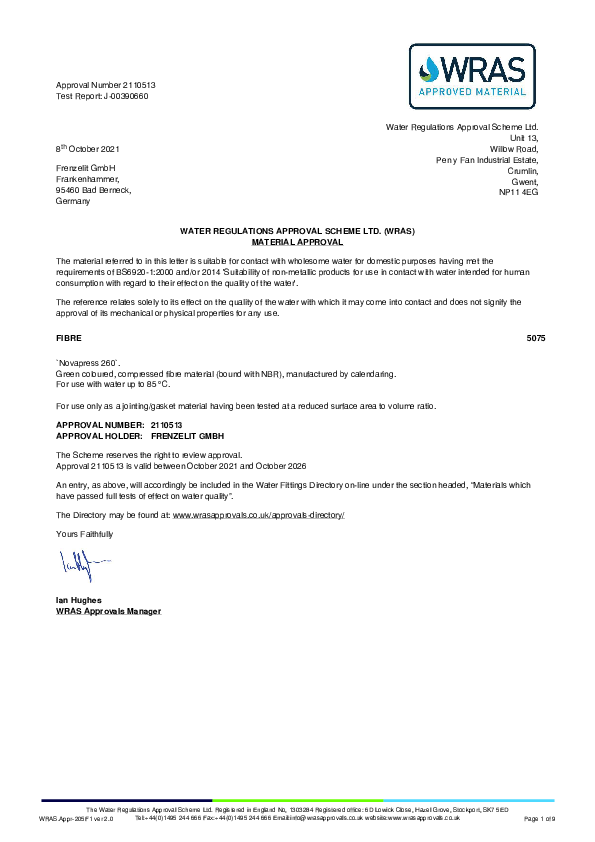

novapress® 260 delivers first-class performance at a very affordable price. This standard gasket is perfect for general industry applications under low and medium pressure temperature loads as well as for uncritical media.

novapress® 260 is approved for use with gas and drinking water, making it the ideal solution not only in the field of heating and plumbing but also for many other applications such as pipeline construction, plant & mechanical engineering and more.

novapress® 260 has an anti-stick coating on both sides and offers excellent cutout utilization thanks to its sheet dimension of 1500 x 2000 mm.