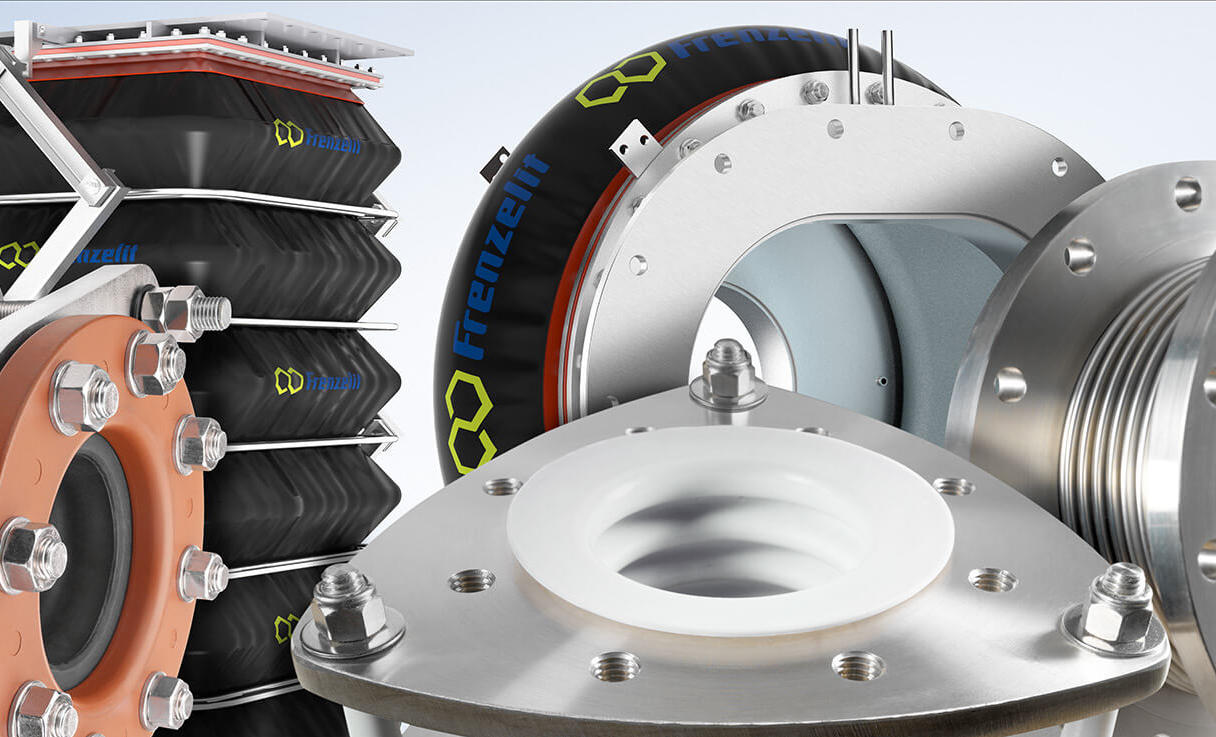

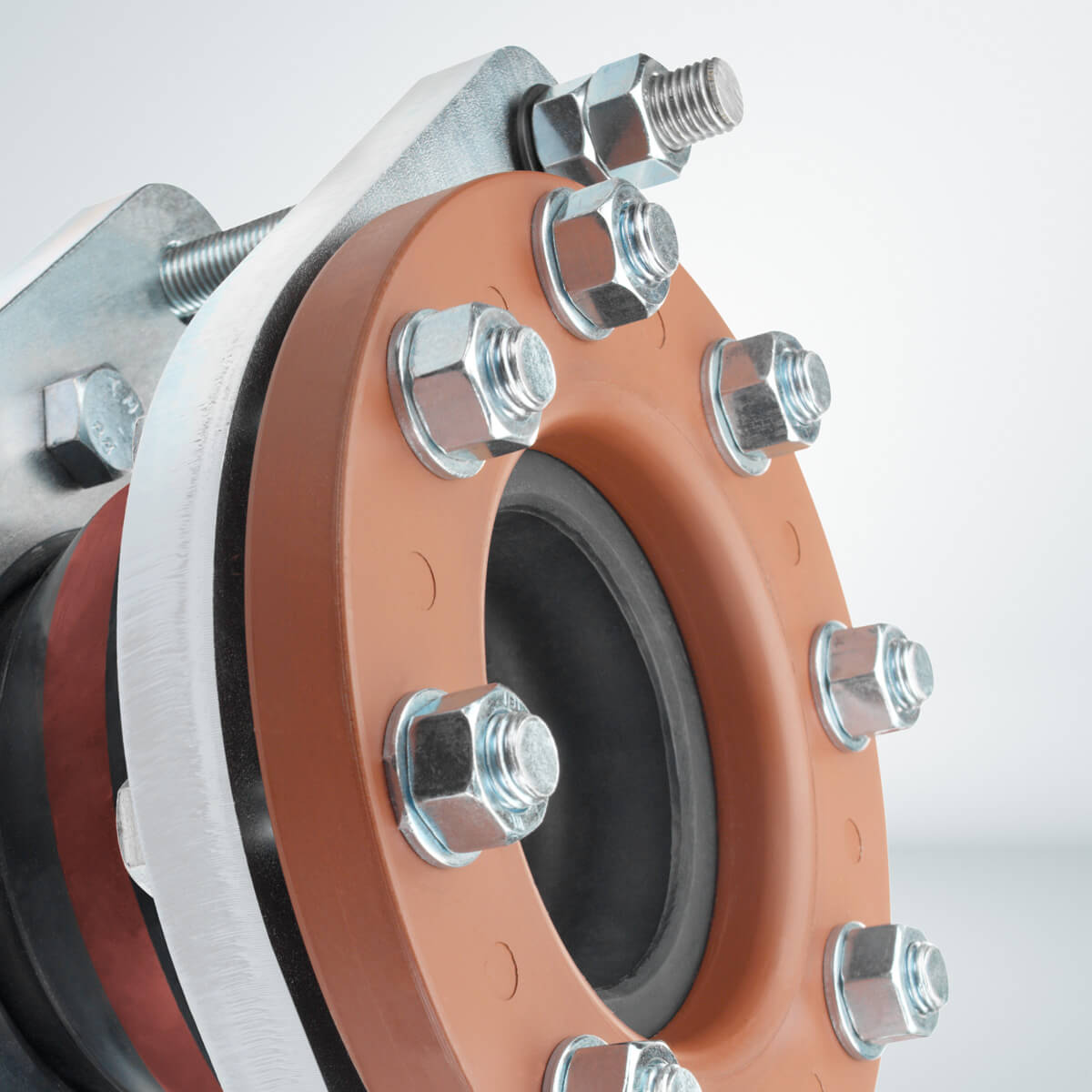

Rubber Expansion Joints

Available materials for highFLEX SFR rubber expansion joints:

- Neoprene

- EPDM

- Butyl

- Nitrile

- Hypalon®

- Viton®

- Natural rubber

- It is also possible to combine different elastomers as inner and outer layers for individual expansion joint types

Possible designs:

- Sealing surface for rotating flanges, both ends with hardened steel insert

- Loose-type flange with groove according to DIN PN 10/16 or ANSI 150 lb

- Full-face elastomer flanges with fabric reinforcement

- Counterflanges with support collar

- Female thread connection for DN 15 - 80 mm

- Length limiters (tie rods)

- Special tie rods for lateral expansion joints

- PTFE inner liner

- Vacuum support rings/spiral supports

easyFLEX tailor made expansion joints:

These expansion joints are specifically designed for materials handling and weighing applications. They are characterized by low adjustment forces with high pressure resistance/resistance to pressure surges.

Materials (examples):

- Silicone rubber – white, red or black

- EPDM

- Fluoroelastomer (Viton®)

Inserts (reinforcements – examples):

- Polyester fabric

- novaTEX® woven fabric (aramid/Kevlar®)

- isoGLAS® woven fabric

Support rings:

- Internal stainless steel rings

- Stainless steel rings bounded to elastomer

Flange design:

- Full-face rubber flanges – unpunched, punched

- Different connection flanges / bolt hole pattern

- Conical shape

- Transition from round to angular

Application examples:

- Handling of plastic granulate

- Scales for coal dust and toner

- Transportation of color pigments

Viton®, Hypalon® and Kevlar® are registered trademarks of DuPont.

- System solutions

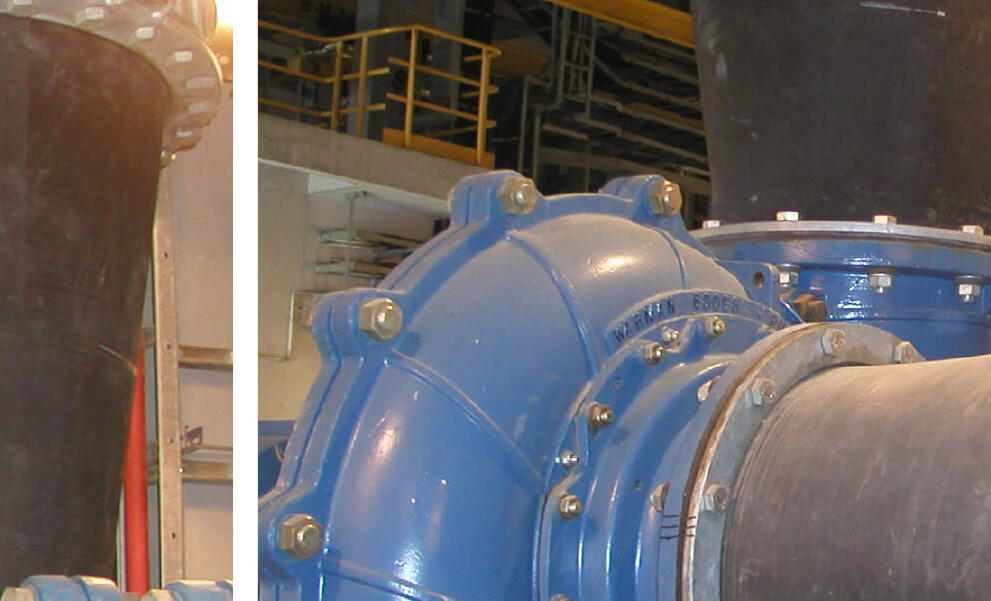

Rubber expansion joints – system solution

Certifications, approvals and tests:

- Application areas

Certifications, approvals and tests:

- Documents and downloads

Certifications, approvals and tests:

- Types

The expansion joint types, movements, temperature and pressure variations shown are only valid for the values provided in the example.

Rubber expansion joints may have the same construction and movement absorption, but they can be designed with a different material structure for use in different application areas.

highFLEX

Certifications, approvals and tests:

- Service

Service

Expansion joints must withstand loads like the system component or pipe itself absorb and additional stress, movements, oscillations or vibrations in axial and/or lateral direction – while ensuring operational safety.

You may already have a very good idea what your expansion joint should look like. Or an application that you want to further develop. A partnership with Frenzelit allows you to realize your ideas according to your system-specific requirements.

We offer you the following:

Frenzelit engineers work together with your design department to develop a technically and economically feasible solution that meets your demands. Our experts are at your disposal in all project phases to develop fabric, non-metallic and elastomer expansion joints, PTFE and multi-laminated PTFE expansion joints as well as rubber and metal expansion joints for your system. We are with you every step of the way – from planning and production to installation and maintenance – for the life of your system.Personal, on-site consulting ensures that your employees stay focused on what they do best, saves valuable resources and gets you the results you need faster. We develop, design or optimize expansion joints in collaboration with your team based on your specifications – so you can rest assured that they will continue to meet tomorrow’s demands. That’s why our motto is “creating hightech solutions”.

Certifications, approvals and tests: